1. Was ist das alkalische Immersionsverfahren

Die Herstellungsmethode von Hydroxypropylmethylcellulose, die alkalische Immersionsmethode, ist auch als Schritt-für-Schritt-Methode bekannt. Diese Produktionsmethode wurde in China in den 1980er Jahren entwickelt. Der Rohstoff für Hydroxypropylmethylcellulose ist raffinierte Baumwolle, und mancherorts wird auch Harz für die Herstellung von Hydroxypropylmethylcellulose verwendet. Darüber hinaus enthält die Zusammensetzung von Hydroxypropylmethylcellulose Elemente wie Methyl, Propylenoxid und Methylchlorid. Der Gehalt an Methylgruppen bestimmt bis zu einem gewissen Grad die Verdickungswirkung von Celluloseether. Daher sind diese drei Stoffe unverzichtbare Rohstoffe bei der Herstellung von Hydroxypropylmethylcellulose.

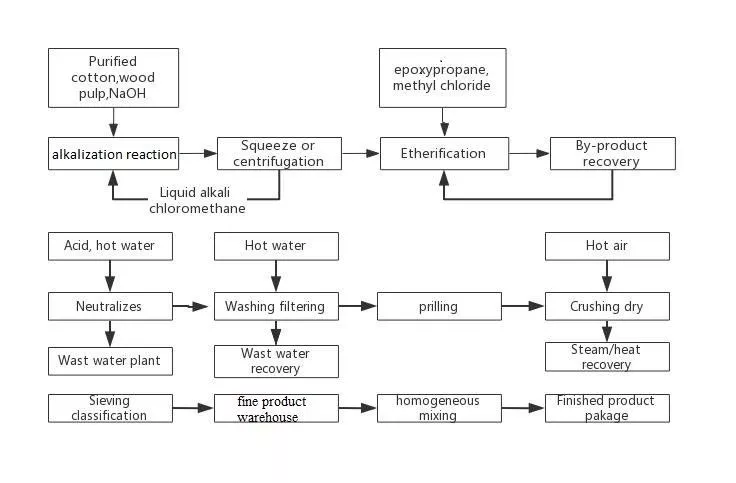

Bei der alkalischen Immersionsmethode wird raffinierter Baumwoll- oder Holzzellstoff mit flüssiger Natronlauge imprägniert, ausgepresst, um überschüssige alkalische Flüssigkeit zu entfernen, um die alkalische Zellulose zu erhalten, dann werden Lösungsmittel und Veretherungsmittel zugegeben, und die Veretherungsreaktion wird bei einer bestimmten Temperatur und einem bestimmten Druck durchgeführt. Am Ende der Reaktion wird das fertige Produkt je nach gewünschtem Veretherungsgrad neutralisiert, gewaschen, getrocknet, zerkleinert und dergleichen.

Das Eintauchen in die Lauge erfolgt wie folgt:

Zunächst wird nicht zerkleinerte, flockige Zellulose in eine exklusiv verwendete Imprägniermaschine gegeben. Die Alkalisierung kann mit mehr als dem sechsfachen Volumen einer alkalischen Flüssigkeit durchgeführt werden. Nach dem Entfernen der überschüssigen alkalischen Flüssigkeit wird die Zellulose dann in einen vertikalen Reaktor mit einer starken Rührvorrichtung gegeben und in etwa dem achtfachen Volumen an Methylchlorid dispergiert. Dann wird eine bestimmte Menge Propylenoxid zugegeben, damit die chemische Reaktion abläuft. Nach Abschluss der Reaktion werden das umgesetzte Methylchlorid, Propylenoxid und das Nebenprodukt Dimethylether zurückgewonnen. Das Endprodukt wird durch Waschen mit heißem Wasser, Trocknen, Zerkleinern und Sieben gewonnen.

Das Flussdiagramm des Produktionsverfahrens ist in der folgenden Abbildung dargestellt:

2. Die wichtigsten Geräte, die bei der alkalischen Immersionsmethode verwendet werden:

| Name der Ausrüstung | Bemerkungen | Name der Ausrüstung | Bemerkungen |

| Alkalische Zellulose-Tauchmaschine | / | Lufttrockner | / |

| Vertikaler Reaktor | Horizontaler Reaktor ist anwendbar | Superfeines Mahlwerk | / |

| Vertikale Waschtrommel | / | Wassertank | / |

| Vakuumbandfilter oder Sedimentationszentrifuge | Rotierender Waschmaschinenfilter | Messbehälter | / |

3. Die wichtigsten Parameter der alkalischen Immersionsmethode:

| Artikel | Bezug der Verbrauchsquote | Artikel | Bezug der Verbrauchsquote | ||

| Rohmaterialien | Zellulose/T | 0.94-1.00 | Strom | Wasser/t | 50.00-60.00 |

| 40% Alkalische Flüssigkeit/T | 2.00-2.20 | Elektrizität/kWh | 2000-2500 | ||

| Methylchlorid/T | 1.20-1.50 | Dampf/t | 9.00-10.00 | ||

| Propylenoxid/T | 0.20-0.23 | ||||

4. Die Vor- und Nachteile der alkalischen Immersionsmethode

Das mit der alkalischen Immersionsmethode hergestellte HPMC hat eine gute Stabilität, da es die gesamte 12-stündige Reaktion durchläuft. Die Anzahl der Verunreinigungen im Endprodukt ist sehr gering. Daher ist die HPMC in hoher Reinheit erhalten werden kann.

Die Produktionsmethode erfordert jedoch eine große Menge an Methylchlorid als Dispergiermittel und der gewünschte Reaktionsdruck beträgt bis zu 3,0 MPa. Nach Abschluss der Reaktion muss eine große Menge an Methylchlorid und Dimethylether zurückgewonnen werden. Der Rohstoffverbrauch und die Menge des chemischen Sauerstoffbedarfs (CSB) im Abwasser sind hoch. Die Qualität des Endprodukts, das mit dieser Methode hergestellt wird, ist garantiert. Der Preis des Endprodukts ist jedoch aufgrund des hohen Personal-, Material- und Zeitaufwands hoch.

Der Betrieb der alkalischen Auslaugung erfordert einen intermittierenden Betrieb, und die Qualität des Produkts ist nicht stabil. Die verbesserte Methode ist die kontinuierliche Alkalisierung und Veretherung, Reinigungstechnologie zu verwenden. Im nächsten Artikel wird melacoll Ihnen eine weitere Methode zur Herstellung von Hydroxypropylmethylcellulose vorstellen - die Verfahren zur Herstellung einer flüssigen Phasedie auch als Slurry-Verfahren bekannt ist. Wir geben Ihnen eine kurze Einführung in den Prozessablauf sowie die Vor- und Nachteile dieser Produktionsmethode.

Eine Antwort hinterlassen