1. Was ist die Methode der Flüssigphasenproduktion?

Die Flüssigphasen-Produktionsmethode (Aufschlämmungsmethode) zur Herstellung von HPMC erfordert ein gemischtes System aus Aceton, Isopropanol, tert-Butanol, Toluol, 1,2-Methoxyethan oder minderwertigen Kohlenwasserstoffen und einer kleinen Anzahl minderwertiger Alkohole als Lösungsmittel (oder Dispergiermittel), um die Cellulose vollständig mit dem Alkali zu vermischen, Methylchlorid, Propylenoxid und dergleichen in einem Aufschlämmungssystem wie dem flüssigen Aufschlämmungszustand, um die Alkalisierungs- und Veretherungsreaktion der Zellulose abzuschließen. Bei dieser Produktionsmethode müssen die Rohstoffe Holz- und Baumwollzellulose im Voraus zerkleinert werden.

Das spezifische Verfahren zur Herstellung von MelaColl™ HPMC in der Flüssigphase richtet sich nach den Leistungs- und Indexanforderungen des Produkts. Der Hersteller kann folgende Verfahren anwenden die Methode der Alkalisierung → Veretherung oder die sequentielle Alkalisierung → Veretherung → sekundäre Alkalisierung → sekundäre Veretherung als mehrstufige Methode, um ein Endprodukt mit besserer Einheitlichkeit und einem höheren Substitutionsgrad zu erhalten.

Das Besondere HPMC-Herstellungsverfahren: Der Hersteller kann das zerkleinerte Zellulosepulver in einem vertikalen oder horizontalen Reaktor mit einem starken Rührwerk in einem Lösungsmittel dispergieren, dann wird eine bestimmte Menge alkalischer Flüssigkeit, Propylenoxid und Methylchlorid zur Veretherung und Reaktion zugegeben. Nach Abschluss der Reaktion wird das Endprodukt durch Waschen mit heißem Wasser, Trocknen, Zerkleinern und Sieben gewonnen.

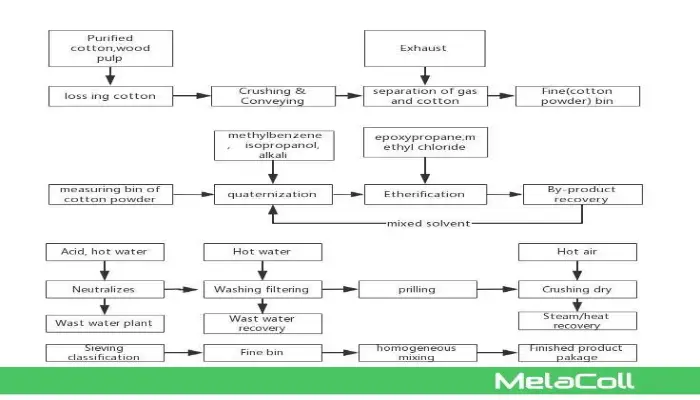

Das Flussdiagramm des Produktionsverfahrens ist in der folgenden Abbildung dargestellt:

Die Hauptausrüstung für die Flüssigphasen-Produktionsmethode:

| Artikel | Verbrauchsquote | Artikel | Verbrauchsquote | ||

| Rohmaterialien | Zellulose/T | 0.84-0.88 | Rohmaterial | Ein gemischtes Lösungsmittel aus Toluol und Isopropanol/t | 0.07-0.10 |

| 50% Alkalische Flüssigkeit/T | 0.86-1.00 | Strom | Wasser/t | 50.00-60.00 | |

| Methylchlorid/T | 0.57-0.70 | Elektrizität/kWh | 3000-3500 | ||

| Propylenoxid/T | 0.19-0.21 | Dampf/t | 8.00-9.00 | ||

Bei der Herstellung werden die gemischteren Lösungsmittel Toluol und Isopropanol als Dispergiermittel verwendet. Der bei der Herstellung verwendete Hauptreaktionsdruck beträgt weniger als 1 MPa. Nach Abschluss der Reaktion wird das Lösungsmittelgemisch aus Toluol und Isopropanol zurückgewonnen wird.

Die Produktionstechnologie ermöglicht die Herstellung von Polyvinylchlorid (PVC), HPMC-Produkte in Bauqualität, pharmazeutischer Qualität und Lebensmittelqualität.

2. Die Vorteile und Mängel der Flüssigphasen-Produktionsmethode

Die Produktionsmethode in flüssiger Phase hat folgende Vorteile: Der Innendruck der Reaktionsanlage ist gering, der Druckbedarf der Anlage ist niedrig, und die Gefahr ist minimal. Nach der Imprägnierung der Zellulose in der alkalischen Lösung wird die Zellulose vollständig expandiert, und die alkalische Zellulose und die alkalische Flüssigkeit können gleichmäßig alkalisiert werden, um eine bessere Infiltration und Quellung der Zellulose zu erreichen. Der Veretherungsreaktor ist klein, und die alkalische Zellulose ist gleichmäßig gequollen, so dass der Hersteller die Produktqualität leicht kontrollieren kann, um eine bessere Einheitlichkeit in Bezug auf den Substitutionsgrad und die Viskosität zu erreichen. Außerdem kann der Hersteller die gewünschte Produktsorte leicht ändern.

Die Flüssigphasen-Produktionsmethode hat aber auch folgende Nachteile: Der Reaktor ist in der Regel nicht allzu groß (unter 15 m3), und die Kapazität ist aufgrund statistischer Zwänge gering. Um die Produktion zu steigern, muss mehr als ein Reaktor hinzugefügt werden. Das Raffinieren und Reinigen von Rohprodukten erfordert eine Menge Ausrüstung, komplexe Vorgänge und einen hohen Arbeitsaufwand. Da keine Formbeständigkeits- oder Compoundierungsbehandlung durchgeführt wird, werden die Viskositätsstabilität des Produkts und die Produktionskosten beeinträchtigt. Sobald ein Hersteller diese manuelle Verpackungsmethode anwendet, werden seine Arbeitsintensität und seine Kosten teurer.

Der Automatisierungsgrad der Reaktionskontrolle ist bei der Flüssigphasen-Produktionsmethode geringer als bei der Gasphasen-Produktionsmethode, so dass die Präzision der Kontrolle geringer ist. Anders als bei der Gasphasenproduktion ist bei der Flüssigphasenproduktion ein komplexes System zur Lösungsmittelrückgewinnung erforderlich. Gegenwärtig werden einige neue Produktionstechnologien entwickelt, und auch die Formel von Hydroxypropylmethyl wird ständig verbessert, um den besonderen Anforderungen von Produkten in verschiedenen Bereichen gerecht zu werden. Darüber hinaus werden neben hpmc ständig neue Mischether entwickelt.

Eine Antwort hinterlassen