Wie man die Fliesenkleber? In den vorangegangenen Artikeln haben wir den Grund analysiert warum Fliesen fall an den Wänden. Die falsche Anwendung von Fliesenkleber ist ein wichtiger Faktor bei diesem Phänomen. In diesem Artikel zeigen wir Ihnen, wie Sie den Fliesenkleber auftragen.

Fliesenkleber ist ein Klebematerial auf Zementbasis für Fliesen. Es gibt verschiedene Zusatzstoffe in Formel für Fliesenkleber. Fliesenkleber ist eine der wichtigsten Arten von Trockenmörteln und kann zur Befestigung von Keramikfliesen, polierten Fliesen und Natursteinen wie Granit verwendet werden. Sie bestehen aus Zuschlagstoffen, Portlandzement, einer kleinen Menge gelöschtem Kalk und funktionellen Zusatzstoffen, die je nach den Anforderungen an die Produktqualität hinzugefügt werden.

Der Fliesenkleber ist das ideale Material für die Verklebung von Fliesen, und die von uns verwendete Methode zum Auftragen des Fliesenklebers ist als Dünnpastenmethode bekannt. Die Dünnbettmethode stellt höhere Anforderungen an die Ebenheit der Grundschicht, die weniger als 3 mm betragen muss. Gleichzeitig muss die Vertikalität der Grundschicht weniger als 3 mm betragen.

1. Wie man Fliesenkleber aufträgt?

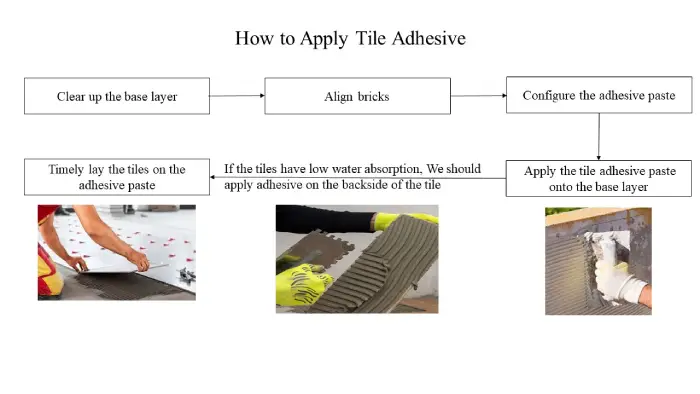

Die Schritte sind wie folgt dargestellt:

1.1 Reinigung der Grundschicht, um sie sauber und stabil zu halten.

1.2 Verwendung von Hängedraht zum Ausrichten von Ziegeln.

1.3 So konfigurieren Sie die Klebepaste:

Wasser in einen Mischbehälter geben, dann den Fliesenkleber zum Mischen hineingießen, etwa 5-10 Minuten lang rühren, um eine gleichmäßige Paste zu bilden, und dann 3-5 Minuten lang reifen lassen und dann ein zweites Mal rühren.

1.4 Zum Auftragen der Fliesenkleberpaste auf den Untergrund mit einem Zahnspachtel in Streifenform kämmen.

Wenn die Oberfläche der Klebepaste trocken ist, muss die trockene Klebepaste abgekratzt und eine neue Schicht Klebepaste aufgetragen werden. Der Benutzer muss eine Schicht der Klebepaste auf die Rückseite der großformatigen Fliesen oder Fliesen mit tieferen Rillen auf der Rückseite auftragen. Der Benutzer muss die Schichtdicke der Klebepaste innerhalb von 4 mm kontrollieren.

Wenn es sich um eine vollformatige Keramikfliese handelt, keramische Flieseoder anderen Fliesen mit geringer Wasseraufnahme, wird empfohlen, den Fliesenkleber auf der Rückseite der Fliese aufzutragen.

1.5 Verlegen Sie die Fliesen rechtzeitig auf der Klebepaste.

1.6 Verwendung der Fliesenmaschine oder anderer Werkzeuge zur Korrektur der Fliesenposition.

2. die beiden Hauptprobleme bei der Verlegung von Fliesen sind die folgenden:

2.1 Die Abstimmung der Materialien muss angemessen sein.

Die Abstimmung der Materialien kann sich vor allem in den folgenden Aspekten manifestieren:

★ Der Fliesenkleber muss der Spezifikation und dem Materialtyp der vorhandenen Fliese entsprechen, und die wasserabsorbierende Fliese muss mit dem Fliesenkleber C2 kombiniert werden.

★ Der Benutzer muss den Fliesenkleber auf der Rückseite des großen Ziegels oder des schweren Ziegels mit geringer Wasseraufnahme auftragen.

2.2 Der Prozess des Auftragens von Fliesenkleber

Bei der Anwendung des Fliesenklebers müssen folgende Aspekte beachtet werden:

★ NICHT Zement oder Sand auf die Oberfläche des Fliesenklebers auftragen;

★ Die Schichtdicke des Fliesenklebers darf nicht mehr als 10 mm betragen;

★ Verhältnis: 3.3:1 (20 kg/Sack, passend zu etwa 6 kg Wasser);

★ Mischen Sie kein Wasser und rühren Sie den bereits getrockneten Mörtel nicht zur Wiederverwendung an;

★ Der Benutzer muss den Fliesenkleber sofort nach dem Aufrühren auftragen, und der Benutzer muss die Nutzungsdauer innerhalb 2 Stunden.

Als ideales Material für die Verklebung von Fliesen erfordert der Fliesenkleber nicht nur die richtige Auswahl, sondern auch die richtige Anwendungsmethode, um die Leistung des Materials zu maximieren. Um mehr über Fliesenkleber zu erfahren, lesen Sie bitte MelaColl folgen. Wir sind ein professioneller Anbieter von Celluloseether mit intensiver Forschung im Bereich Fliesenkleber. Fliesenkleber sind eine der umfangreichsten Anwendungen für unsere MelaColl™ Celluloseether. Wir bieten wirtschaftliche, Standard- und Premiumprodukte für Fliesenkleber.

Unsere MelaColl™-Produkte bieten bei Fliesenkleberanwendungen die folgenden Eigenschaften:

- Verbesserte Durchhangfestigkeit

- Verbesserte Verarbeitbarkeit

- Verbesserte Adhäsion

- Verbesserte Hitze- und Gefrierbeständigkeit

- Verbesserte Wasserrückhaltung

Eine Antwort hinterlassen