RDP en el pegamento de baldosas mejora significativamente el rendimiento del pegamento de baldosas. En comparación con otros materiales de decoración de paredes y suelos, las baldosas cerámicas presentan excelentes ventajas en cuanto a limpieza, cuidado y durabilidad, y se han convertido en un material de construcción indispensable en la arquitectura moderna.

Con la continua expansión del campo de aplicación de las baldosas cerámicas y el rápido desarrollo de la tecnología de fabricación, la calidad de las baldosas cerámicas ha mejorado enormemente. El proceso tradicional de pegado de baldosas cerámicas ya no puede satisfacer sus requisitos de aplicación.

Por esta razón, los fabricantes de materiales de construcción han introducido sucesivamente adhesivo para baldosas modificado con polvo de polímero redispersable (RDP). Su objetivo es mejorar el rendimiento de adhesión del adhesivo para baldosas cerámicas y simplificar el proceso de construcción del pegado de baldosas cerámicas. De acuerdo con los resultados experimentales, este artículo trata principalmente del análisis del rendimiento del RDP en el adhesivo para baldosas.

Por esta razón, los fabricantes de materiales de construcción han introducido sucesivamente adhesivo para baldosas modificado con polvo de polímero redispersable (RDP). Su objetivo es mejorar el rendimiento de adhesión del adhesivo para baldosas cerámicas y simplificar el proceso de construcción del pegado de baldosas cerámicas. De acuerdo con los resultados experimentales, este artículo trata principalmente del análisis del rendimiento del RDP en el adhesivo para baldosas.

1. 1. Material y métodos

1.1 Material

(1) Cemento;

(2) Cenizas volantes: cenizas volantes secundarias;

(3) Éter de celulosa: Melacoll, viscosidad de unos 60.000;

(4) RDP: Mikrant;

(5) Arena: secar la arena y cribarla en diferentes tamaños de partícula según sea necesario;

(6) Agua de mezcla: agua del grifo.

1.2 Métodos

Este experimento investiga principalmente la resistencia a la tracción del adhesivo para baldosas tras el envejecimiento térmico y la inmersión en agua. La preparación, el mantenimiento y los métodos experimentales de las muestras se llevarán a cabo de acuerdo con las disposiciones pertinentes de las normas pertinentes.

(1) Los ingredientes del polvo adhesivo para baldosas: pesar el cemento, la arena de cuarzo, los éteres de celulosa y otras materias primas en una determinada proporción, añadirlos a una mezcladora y removerlos uniformemente.

(2) La preparación del adhesivo para baldosas: En primer lugar, añada los ingredientes en polvo correspondientes a su consumo de agua en un recipiente de mezcla, añada los ingredientes en polvo experimentales correspondientes y mezcle bien y uniformemente durante 30 segundos con un mezclador de mortero.

2. Resultado y análisis

2.1 Influencia de la dosificación de RDP en la resistencia a la tracción del adhesivo para baldosas.

Tabla 1: En la tabla siguiente se muestra el efecto del RDP sobre la fuerza de adherencia del adhesivo para baldosas cerámicas.

| EXPERIMENTO NO. | CANTIDAD DE MEZCLA DE RDP/% | RESISTENCIA ADHESIVA ORIGINAL DEL RDP/MPa | resistencia a la inmersión en agua/MPa | resistencia al envejecimiento térmico/MPa |

| 1 | 1.5 | 1.15 | 0.81 | 0.52 |

| 2 | 3 | 1.13 | 0.84 | 0.67 |

| 3 | 4.5 | 1.24 | 0.85 | 0.75 |

Según la Tabla 1, la resistencia del adhesivo cementoso para baldosas tras la inmersión en agua y la resistencia tras el envejecimiento térmico muestran una tendencia creciente con el aumento de la dosificación de RDP. Entre ellos, la tendencia al aumento más evidente es el rendimiento del envejecimiento térmico. La razón es que la flexibilidad del adhesivo para baldosas aumenta con el incremento del PDR (mientras que la cantidad de otras materias primas permanece invariable).

El daño causado por el correspondiente cambio de fuerza a alta temperatura en el rendimiento de adhesión del adhesivo para baldosas se reduce, lo que se manifiesta en la mejora del rendimiento de adhesión, y se refleja directamente en el aumento de la resistencia a la tracción de la adhesión tras el envejecimiento térmico que se muestra en la Figura 2-1. La dirección fuerza de van der Waals en la interfaz entre el adhesivo y la baldosa cerámica se destruye por la entrada de agua tras la inmersión.

En general, manteniendo inalterada la proporción de mezcla de otras materias primas y añadiendo polímero en polvo, la viscosidad de la pasta disminuye en cierta medida. El aumento de la dosificación de RDP en el adhesivo de azulejos reducirá el espesor de la pasta de azulejos. La mejora de la compacidad del adhesivo para baldosas dificulta la entrada de agua en el interior del adhesivo para baldosas, y la tendencia al fallo de la fuerza de van der Waals se ralentiza, lo que puede mejorar las propiedades de adhesión a la tracción del adhesivo para baldosas cerámicas después de sumergirlo en agua.

Como se ha mencionado anteriormente, la resistencia a la tracción del adhesivo para baldosas tras el remojo en agua y tras el envejecimiento térmico aumentará con la cantidad de mezcla de polvo de polímero redispersable. Este fenómeno puede deberse a la estrecha relación entre la resistencia al envejecimiento térmico y la flexibilidad del adhesivo para baldosas para la notable mejora de la resistencia al envejecimiento. La flexibilidad del RDP y del adhesivo para baldosas está directamente relacionada. Teniendo en cuenta las propiedades y el precio del adhesivo para baldosas, la mejor dosificación de polvo es 3%.

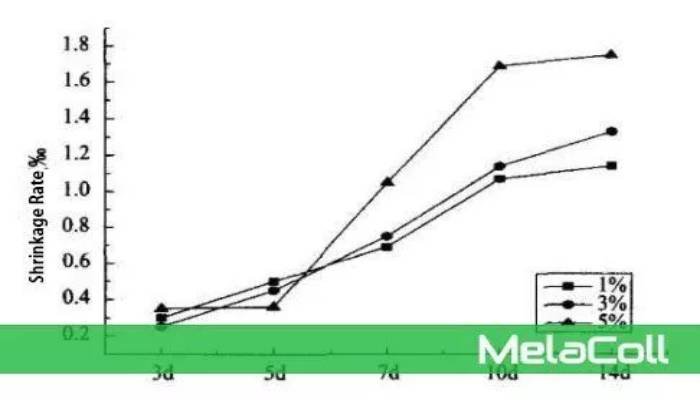

2.2 A continuación se muestra el efecto del PDR sobre la contracción de las baldosas cerámicas.

Figura 1: Efecto de la cantidad de mezcla de RDP en el rendimiento de retracción del adhesivo para baldosas

Según la figura 1, el valor de contracción del adhesivo para baldosas cerámicas aumentará con el incremento de la edad.

Antes de la edad de 10 días, el valor de la contracción aumentó significativamente. Después de diez días, la deformación por contracción se ralentizará. El cambio del valor de contracción del adhesivo para baldosas cerámicas está estrechamente relacionado con el mecanismo de acción de las materias primas en el adhesivo para baldosas cerámicas. Como material mixto con actividad hidráulica potencial, las cenizas volantes tienen una pobre capacidad de reacción química temprana y una baja energía superficial de las partículas. El agua entre las partículas de ceniza volante se evapora y se pierde rápidamente.

Sin embargo, el cemento se encuentra en un periodo de hidratación "severo" en esta fase, y el aumento de la contracción temprana es relativamente significativo. Con el desarrollo de la edad de curado, bajo la excitación del Ca(OH) liberado por la hidratación del cemento, las cenizas volantes experimentan una hidratación secundaria. La estructura del adhesivo para baldosas cerámicas se vuelve más densa, la resistencia mejora considerablemente y la deformación por contracción del adhesivo para baldosas cerámicas se ralentiza.

Según la figura 1, el valor de deformación por contracción del adhesivo para baldosas cerámicas aumentará con el aumento de la cantidad de mezcla de RDP en el adhesivo para baldosas. Cuando la cantidad de mezcla de RDP en el adhesivo para baldosas es de 5%, el valor de contracción del adhesivo para baldosas cerámicas se aproxima a 0,2%. La razón puede ser que la incorporación de RDP mejora la flexibilidad del adhesivo cementoso para baldosas cerámicas. Con el aumento de la cantidad de mezcla de RDP, la rigidez del adhesivo para baldosas cerámicas disminuirá, la flexibilidad aumentará, y la resistencia del adhesivo para baldosas cerámicas a la deformación por contracción disminuirá, lo que conducirá al aumento del valor de retracción del adhesivo para baldosas cerámicas.

2.3 A continuación se muestra la influencia de la cantidad de mezcla de RDP en la deformación lateral del adhesivo para baldosas.

Figura 2: Efecto de la cantidad de mezcla de RDP en la deformación lateral del adhesivo para baldosas

A partir de la Figura 2, podemos ver que el polvo de polímero redispersable tiene una gran influencia en la capacidad de deformación lateral del adhesivo para baldosas. El valor de deformación lateral del adhesivo para baldosas aumentará con la cantidad de mezcla de RDP. Cuando la cantidad de mezcla de RDP en el adhesivo para baldosas es 2%, su deformación lateral será superior a 2,5 mm, lo que puede cumplir los requisitos de la norma adhesiva de grado S1. Cuando la cantidad de mezcla de RDP en el adhesivo para baldosas es inferior a 4%, su deformación lateral puede alcanzar más de 5,0 mm, lo que puede cumplir los requisitos de la norma de adhesivos de grado S2.

La razón es que con el aumento de la cantidad de mezcla de RDP en el adhesivo para baldosas, la viscosidad de la lechada del adhesivo para baldosas disminuirá ligeramente, su compacidad aumentará, su fuerza de unión aumentará, y su capacidad antifisuras también aumentará. El RDP en el adhesivo para baldosas tiene un mejor aumento de la tenacidad, por lo que aumenta la capacidad de deformación lateral del adhesivo para baldosas.

3. Conclusión

(1) El polímero redispersable en polvo tiene una influencia significativa en la fuerza de adhesión de formulación de adhesivo cementoso para baldosas. Con el aumento de RDP en la mezcla de adhesivo para baldosas, aumentará la resistencia al agua y la resistencia al envejecimiento del adhesivo para baldosas. Entre ellos, el aumento de la resistencia al envejecimiento es notable.

(2) El valor de contracción del adhesivo para baldosas aumentará con la adición de RDP. Pero la incorporación de RDP en el adhesivo para baldosas es beneficiosa para el rendimiento general del adhesivo para baldosas cerámicas.

(3) La adición de RDP puede mejorar la capacidad de deformación lateral del adhesivo cementoso para baldosas. Cuando la cantidad de mezcla de RDP en el adhesivo para baldosas es de 2%, su deformación lateral puede cumplir los requisitos del grado S1 de la norma adhesiva; Cuando la cantidad de mezcla de RDP en el adhesivo para baldosas es superior a 4%, su deformación lateral puede cumplir los requisitos de la norma adhesiva de grado S2.

Dejar una respuesta