1. ¿Qué es el método de producción en fase líquida?

El método de producción en fase líquida (método de producción de lechada) para producir HPMC requiere un sistema mixto de acetona, isopropanol, terc-butanol, tolueno, 1,2-metoxietano o hidrocarburos de bajo grado y un pequeño número de alcoholes de bajo grado como disolvente (o dispersante) para hacer que la celulosa se mezcle completamente con el alcalino, cloruro de metilo, óxido de propileno y similares en un sistema de suspensión como el estado de suspensión líquida para completar la reacción de alcalinización y eterificación de la celulosa. Este método de producción requiere que las materias primas de celulosa de madera y algodón sean trituradas previamente.

El proceso de operación específico del método de producción en fase líquida de MelaColl™ HPMC se basa en los requisitos de rendimiento e índice del producto. El productor puede adoptar el método de alcalinización → eterificación o adoptar el método secuencial de alcalinización → eterificación → la alcalinización secundaria → la eterificación secundaria multietapa para obtener el producto acabado con una mejor uniformidad y un mayor grado de sustitución.

El específico Proceso de producción de HPMC: El productor puede disponer el polvo fino de celulosa triturado en un reactor vertical u horizontal con un fuerte dispositivo de agitación, dispersado en un disolvente, después se añade una cierta cantidad de líquido alcalino, óxido de propileno y cloruro de metilo para la eterificación y la reacción. Una vez finalizada la reacción, el producto acabado se obtiene mediante lavado con agua caliente, secado, trituración y tamizado.

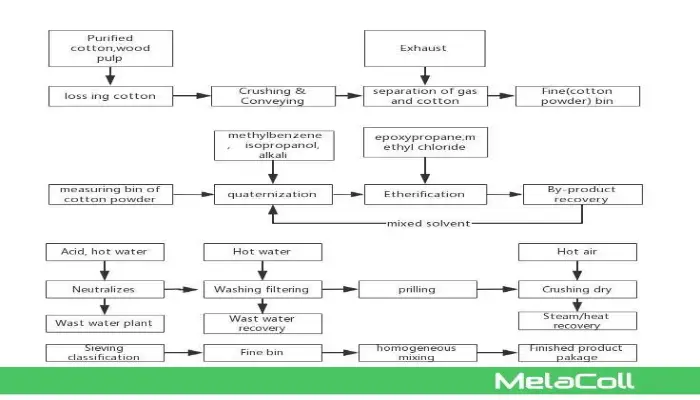

El diagrama de flujo del método de producción se muestra en la siguiente figura:

El equipo principal para el método de producción en fase líquida:

| Artículo | Cuota de consumo | Artículo | Cuota de consumo | ||

| Materias primas | Celulosa/T | 0.84-0.88 | Materia prima | Un disolvente mixto de tolueno e isopropanol/t | 0.07-0.10 |

| 50% Líquido alcalino/T | 0.86-1.00 | Potencia | Agua/t | 50.00-60.00 | |

| Cloruro de metilo/T | 0.57-0.70 | Electricidad/kWh | 3000-3500 | ||

| Óxido de propileno/T | 0.19-0.21 | Vapor/t | 8.00-9.00 | ||

El método de producción adopta los disolventes más mezclados de tolueno e isopropanol como dispersantes. La presión de reacción principal utilizada en el método de producción es inferior a 1MPa. Una vez finalizada la reacción, el disolvente mixto de tolueno y se recupera el isopropanol.

La tecnología de producción permite fabricar policloruro de vinilo (PVC), productos HPMC para la construcción, farmacéuticos y alimentarios.

2. Ventajas e inconvenientes del método de producción en fase líquida

El método de producción en fase líquida tiene las siguientes ventajas: La presión interna del equipo de reacción es pequeña, el requisito de presión del equipo es bajo y el peligro es mínimo. Después de que la celulosa se impregne en la solución alcalina, la celulosa se expande completamente, y la celulosa alcalina y el líquido alcalino pueden someterse uniformemente a la alcalinización para lograr una mejor infiltración e hinchamiento de la celulosa. El reactor de eterificación es pequeño, y la celulosa alcalina se hincha uniformemente, lo que permite al productor controlar fácilmente la calidad del producto para obtener una mayor uniformidad en términos de grado de sustitución y viscosidad. Además, el productor puede cambiar fácilmente la variedad de producto deseada.

Pero el método de producción en fase líquida también presenta las siguientes deficiencias: El reactor no suele ser demasiado grande (menos de 15m3), y la capacidad es pequeña debido a restricciones estadísticas. Es necesario añadir más de un reactor para aumentar la producción. El refinado y la purificación de los productos crudos requieren mucho equipo, operaciones complejas y una gran intensidad de mano de obra. Como no se lleva a cabo ningún tratamiento antimoho ni de composición, la estabilidad de la viscosidad del producto y los costes de producción se ven afectados. Cuando un productor adopta este método de envasado manual, su intensidad de mano de obra y sus costes se encarecen.

El grado de automatización del control de la reacción en el método de producción en fase líquida es inferior al del método de producción en fase gaseosa, por lo que la precisión del control es menor. A diferencia del método de producción en fase gaseosa, el método de producción en fase líquida requiere un complejo sistema de recuperación de disolventes. En la actualidad, se están desarrollando continuamente algunas tecnologías de producción nuevas, y también se está mejorando continuamente la fórmula del hidroxipropilmetilo para satisfacer las necesidades especiales de los productos en diversos campos. Por otra parte, además del hpmc, se desarrollan constantemente nuevos éteres mixtos.

Dejar una respuesta