1. What is the liquid-phase production method?

The liquid-phase production method (slurry production method) of producing HPMC requires a mixed system of acetone, isopropanol, tert-butanol, toluene, 1,2-methoxyethane or low-grade hydrocarbons and a small number of low-grade alcohols as the solvent (or dispersant) to make the cellulose fully mixed with the alkaline, methyl chloride, propylene oxide and the like in a slurry system like the liquid slurry state to complete the alkalization and etherification reaction of cellulose. This production method requires the raw materials of wood and cotton cellulose to be crushed in advance.

The specific operation process of the liquid-phase production method of MelaColl™ HPMC is based on the performance and index requirements of the product. The producer can adopt the method of alkalization → etherification or adopt the sequential alkalization → etherification → the secondary alkalization → the secondary etherification multi-stage method to obtain the finished product with better uniformity and a higher degree of substitution.

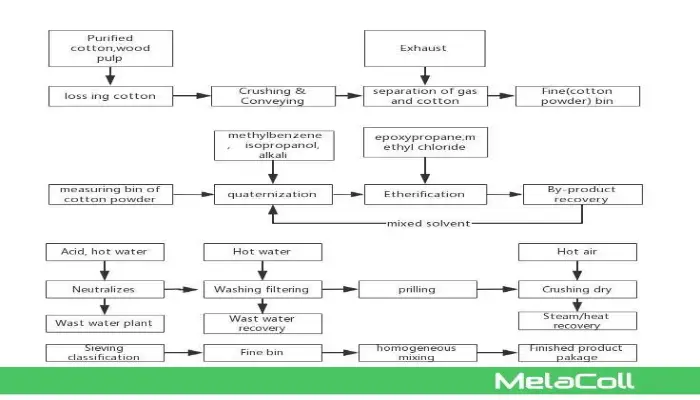

The specific HPMC production process: The producer can arrange the crushed cellulose fine powder in a vertical or horizontal reactor with a strong agitating device, dispersed in a solvent, then a certain amount of alkaline liquid, propylene oxide and methyl chloride are added for etherification and reaction. Upon the completion of the reaction, the finished product is obtained through hot water washing, drying, crushing, and sieving.

The flowchart of the production method is shown in the following figure:

The main equipment for the liquid-phase production method:

| Item | Consumption Quota | Item | Consumption Quota | ||

| Raw Materials | Cellulose/T | 0.84-0.88 | Raw Material | A mixed solvent of toluene and isopropanol/t | 0.07-0.10 |

| 50% Alkaline Liquid/T | 0.86-1.00 | Power | Water/t | 50.00-60.00 | |

| Methyl Chloride/T | 0.57-0.70 | Electricity/kWh | 3000-3500 | ||

| Propylene Oxide/T | 0.19-0.21 | Steam/t | 8.00-9.00 | ||

The production method adopts the more mixed solvents of toluene and isopropanol as dispersants. The main reaction pressure used in the production method is less than 1MPa. Upon the completion of the reaction, the mixed solvent of toluene and isopropanol is recovered.

The production technology allows the production of polyvinyl-chloride-grade (PVC), construction-grade, pharmaceutical-grade, and food-grade HPMC products.

2. The advantages and shortcomings of the liquid-phase production method

The liquid-phase production method has the following advantages: The internal pressure of the reaction equipment is small, the pressure requirement of the equipment is low, and the danger is minimal. After the cellulose is impregnated in the alkaline solution, the cellulose is fully expanded, and the alkaline cellulose and the alkaline liquid can evenly undergo alkalization to achieve better cellulose infiltration and swelling. The etherification reactor is small, and the alkaline cellulose is evenly swollen, which allows the producer to easily control the product quality to obtain a better uniformity in terms of substitution degree and viscosity. Additionally, the producer can easily change the desired product variety.

But the liquid-phase production method also has the following shortcomings: The reactor is usually not too large (below 15m3), and the capacity is small due to statistical constraints. More than one reactor is bound to be added to increase production. The refining and purification of crude products require a lot of equipment, complex operations, and high labor intensity. Because no mold-proof or compounding treatment is carried out, the viscosity stability of the product and the production costs are affected. Once a producer adopts this manual packaging method, their labor intensity and costs become more expensive.

The degree of automation of reaction control in the liquid-phase production method is lower than that in the gas-phase production method, so the precision of control is lower. Unlike the gas-phase production method, the liquid-phase production method requires a complex solvent recovery system. At present, some new production technologies are being continuously developed, and the formula of hydroxypropyl methyl is also being continuously improved to meet the special needs of products in various fields. In addition, in addition to hpmc, new mixed ethers are constantly being developed.

댓글 남기기