Beton, dünyada en yaygın kullanılan inşaat malzemelerinden biridir. Güçlü, dayanıklı ve çok yönlü olması onu kaldırımlardan araba yollarına, gökdelenlerden köprülere kadar her şey için gerekli kılmaktadır. Peki beton yapımında tam olarak ne kullanıldığını hiç merak ettiniz mi?

Özünde beton, birleştirildiğinde sert, kaya benzeri bir malzeme oluşturan birkaç temel bileşenin karışımıdır. Kesin oranlar istenen mukavemete ve uygulamaya bağlı olarak değişebilir, ancak temel bileşenler aynı kalır. Şimdi her bir bileşeni inceleyelim.

Beton Nelerden Yapılır?

Beton yapımında ne kullanılır? Temel bileşenler şaşırtıcı derecede basittir: çimento, su ve agregalar. İşte bu kadar! Kulağa çok basit gelse de, asıl sihir bu bileşenlerin birlikte nasıl çalıştığında yatar.

Çimento

Çimento betonun sadece bir bileşenidir - bağlayıcı madde olarak işlev görür. Kireçtaşı, kil, deniz kabukları ve silis kumundan yapılan bu malzemeler ısıtılır ve alçıtaşı ile öğütülerek Portland çimentosubetonda kullanılan en yaygın türdür.

Bir yandan çimento sadece yaklaşık 10-15% beton karışımının hacim olarak, kimyasal olarak en aktif bileşendir. Su ile karıştırıldığında HİDRASYONBu da sertleşmesine ve diğer malzemeleri birbirine bağlamasına neden olur.

[İlgili: Çimento ve Beton Arasındaki Fark]

Su

Su, çimentoyu katı bir bağlayıcıya dönüştüren kimyasal reaksiyon için gereklidir. Doğru miktarda su çok önemlidir - çok az olursa karışım kuru ve ufalanmış olur; çok fazla olursa beton zayıf ve çatlamaya eğilimli olur.

Bu su-çimento oranı betonun mukavemetini ve dayanıklılığını belirlemede kritik bir faktördür. Tipik bir W/C oranı yaklaşık 0,4 - 0,6'dırBu da her yarım kilo çimento için yaklaşık 0,4 ila 0,6 kilo su kullanmanız gerektiği anlamına gelir.

Agregalar (Kum, Çakıl, Kırma Taş)

Agregalar betonun büyük kısmını oluşturur (toplam hacmin yaklaşık 60-75%'si) ve yapısal güç sağlar. Bunlar genellikle kum, çakıl veya kırma taş gibi maddeleri içerir. Agregalar olmadan, her yerinden çatlayacak ağır ve pahalı bir çimento bloğu elde edersiniz. Agregalar mukavemet ve stabiliteye yardımcı olur ve hatta maliyeti düşürür.

İki türü vardır: ince agregalar (kum gibi) ve iri agregalar (çakıl veya kırılmış kaya gibi). Bu agregaların karışımı ve boyutu, betonun ne için kullanılacağına bağlı olarak değişebilir.

Katkılar (İsteğe Bağlı Ancak Yaygın)

Yukarıdaki üç bileşen teknik olarak beton yapmak için ihtiyacınız olan tek şey olsa da, çoğu modern karışım şunları içerir Katkılar-Belirli özellikleri iyileştiren kimyasallar veya katkı maddeleri. Bazı yaygın türleri şunlardır:

- Akışkanlaştırıcılar (Su azaltıcılar) - Ekstra su eklemeden karışımla çalışmayı kolaylaştırın.

- Hızlandırıcılar - Kürlenme sürecini hızlandırır (soğuk havalarda faydalıdır).

- Geciktiriciler - Kürlenmeyi yavaşlatır (sıcak havalarda veya büyük dökümler için faydalıdır).

- Hava sürükleyici maddeler - Donma-çözülme direncini artırmak için küçük hava kabarcıkları oluşturun.

- Süper Akışkanlaştırıcılar - Çok akışkan betona izin verin (yüksek dayanımlı veya kendiliğinden yayılan karışımlarda kullanılır).

Katkılar özellikle yüksek performanslı yapılar veya dekoratif beton gibi özel beton uygulamalarında önemlidir.

Beton harmanlama için oran nedir?

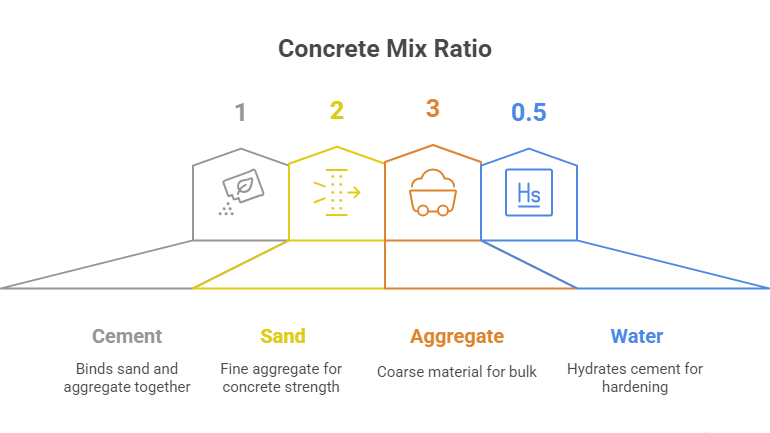

Beton için harmanlama oranından bahsettiğimizde, temel olarak her bir bileşenin karışıma ne kadar gireceğinden bahsediyoruz. Beton için temel karışım oranı (genellikle teraslar, kaldırımlar veya levhalar gibi küçük projelerde kullanılır).

Duyacağınız tipik bir karışım 1:2:3 oranıdır. Bu şu demek:

- 1 ölçek çimento

- 2 parça kum (ince agrega)

- 3 parça çakıl veya kırma taş (kaba agrega)

Sonra eklersiniz su-genellikle yaklaşık 0,5 parçaİşe ve iklime bağlı olarak. Su-çimento oranı çok önemlidir. Daha fazla su, betonla çalışmayı kolaylaştırır, ancak aynı zamanda onu zayıflatabilir. Daha az su daha güçlü beton anlamına gelir, ancak dökülmesi ve bitirilmesi daha zordur.

Bu 1:2:3 karışımı araba yolları, kaldırımlar ve döşemeler gibi genel amaçlı betonlar için mükemmeldir. Ancak köprü destekleri veya yüksek binalar gibi daha ağır işler için karışım değişebilir. Mühendisler, betonun gerekli mukavemet ve dayanıklılığı karşıladığından emin olmak için oranları ayarlayacak ve hatta başka malzemeler ekleyecektir.

Harmanlama hacme göre (kova veya kürek kullanarak) veya ağırlığa göre (daha hassas olan ve daha büyük projelerde kullanılan) yapılabilir. Her iki durumda da tutarlılık önemlidir. Nihai yapının sağlam ve güvenli olması için her partinin mümkün olduğunca aynı olmasını istersiniz.

Beton Nasıl Yapılır?

Pekala, artık içine ne girdiğini bildiğimize göre, bu malzemeyi gerçekte nasıl yapıyorsunuz?

Bu roket bilimi değil, ama kesinlikle bir sanat.

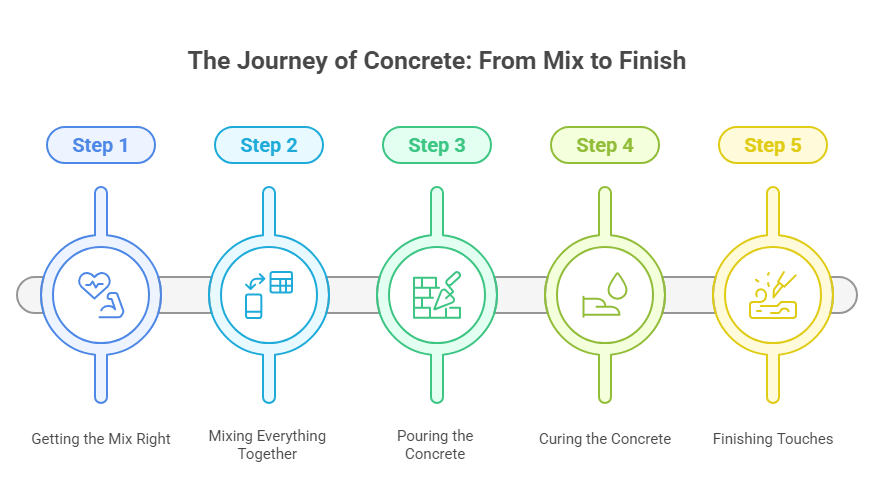

Adım 1: Karışımı Doğru Yapmak

Her şeyden önce doğru oranlara ihtiyacınız var. Bu genellikle "karışım tasarımı" olarak adlandırılır. Farklı işler farklı karışımlara ihtiyaç duyar. Örneğin bir kaldırım, bir köprü ile aynı tür betona ihtiyaç duymaz.

Temel beton için yaygın bir oran 1 ölçek çimento, 2 ölçek kum ve 3 ölçek çakıl ve yaklaşık yarım ölçek su olabilir. Ancak yine de bu oran değişebilir.

Amaç güç, dayanıklılık ve işlenebilirliği dengelemektir. Çok kuruysa dökmesi zor olur. Çok ıslaksa yeterince güçlü olmayabilir.

Adım 2: Her Şeyi Bir Araya Getirmek

Malzemelerinizi ölçtükten sonra sıra karıştırmaya gelir. Bu işlem küçük işler için elle yapılabilir, ancak daha büyük projelerde mikserler kullanılır - ya taşınabilir tamburlu mikserler ya da yolda dönerken gördüğünüz büyük kamyonlar.

Her şey içine atılır: önce agregalar, sonra çimento, sonra su. Ve sonra hepsi güzel ve homojen olana kadar karıştırılır. Kuru yer kalmayacak. Aşırı ıslak noktalar yok. Sadece iyi, eşit bir karışım.

Adım 3: Betonun Dökülmesi

Her şey karıştıktan sonra hızlı hareket etmelisiniz. Beton oldukça hızlı priz almaya başlar. Formlara veya kalıplara döküldükten sonra yayılır ve düzleştirilir. Bu adıma yerleştirme ve şaplama denir.

Daha sonra bir şamandıra ile düzleştirilir. Daha büyük yüzeyler için, güzel ve düz hale getirmek için elektrikli aletler kullanılabilir.

Adım 4: Betonun Kürlenmesi

Şimdi insanların genellikle gözden kaçırdığı bir kısım var: kürleme. Bu sadece kurumaya bırakmak değildir. Kürleme, düzgün bir şekilde sertleşebilmesi için nemli tutmakla ilgilidir. Daha önce bahsettiğimiz hidrasyon süreci? Zaman alır. Genellikle birkaç gün, bazen de haftalar.

Beton çok hızlı kurursa çatlayabilir veya olması gerekenden daha zayıf hale gelebilir. Bu nedenle, insanlar nemi içeride tutmak için üzerine su püskürtebilir, plastikle kaplayabilir veya kürleme bileşikleri kullanabilir.

Adım 5: Son Rötuşlar

Kürlendikten sonra, bazen su ve lekeleri dışarıda tutmak için sızdırmazlık sağlamak veya dekoratif bir yüzeyse doku eklemek gibi biraz daha son işlem yaparsınız.

[İlgili: Betonun Kuruması Ne Kadar Sürer?]

Sonuç

Beton basit bir malzeme gibi görünebilir, ancak güç, dayanıklılık ve çok yönlülük sağlamak için birlikte çalışan bileşenlerin yüksek mühendislik ürünü bir karışımıdır. Temel bileşenler-çimento, su ve agregalar-karışımın çekirdeğini oluştururken katkılar ve tamamlayıcı malzemeler Çok çeşitli inşaat ihtiyaçlarını karşılamak için özelliklerine ince ayar yapın.

İster bir kaldırım dökün ister bir gökdelen inşa edin, betondaki bileşenleri anlamak daha iyi performans, daha düşük maliyet ve daha sürdürülebilir bir yapılı çevre sağlamaya yardımcı olur.

Bir Cevap Bırakın