È necessario capire cos'è il MHEC per conoscerne l'uso.

Che cos'è il MHEC?

MHEC è l'abbreviazione di metilidrossietilcellulosa. Metilidrossietilcellulosa (HEMC) è un composto organico con formula chimica C2H6O2-xCH4O. È un addensante e un agente protettivo, ampiamente utilizzato nei rivestimenti in lattice a base d'acqua, nell'edilizia e nei materiali da costruzione, negli inchiostri da stampa, nella perforazione petrolifera e in altri campi, per addensare e trattenere l'acqua e migliorare le prestazioni di costruzione.La metilidrossietilcellulosa (MHEC) è un componente fondamentale nella formulazione degli adesivi per piastrelle, in quanto offre una serie di vantaggi che migliorano le prestazioni e la qualità delle installazioni di piastrelle. Questo articolo approfondisce i vari ruoli che il MHEC svolge negli adesivi per piastrelle e i fattori da considerare nella scelta del MHEC appropriato per applicazioni specifiche.

-

Ruolo del MHEC nell'adesivo per piastrelle

Il MHEC è un derivato dell'etere di cellulosa che funge da addensante, agente di ritenzione idrica e modificatore reologico nei materiali da costruzione, compresi gli adesivi per piastrelle. La sua inclusione nelle formulazioni degli adesivi per piastrelle è essenziale per migliorare la lavorabilità, il tempo aperto e le proprietà di adesione. Controllando il comportamento reologico dell'adesivo, il MHEC garantisce un'applicazione e un incollaggio corretti delle piastrelle, con conseguenti installazioni durevoli e di lunga durata.

-

Proprietà chiave del MHEC nell'adesivo per piastrelle

Quando si sceglie il MHEC come adesivo per piastrelle, è necessario considerare diverse proprietà chiave:

Viscosità: La viscosità del MHEC influenza la lavorabilità e le caratteristiche di applicazione dell'adesivo per piastrelle. I gradi a viscosità più elevata sono adatti per applicazioni verticali e sopraelevate, mentre quelli a viscosità più bassa sono preferibili per facilitare la spatolatura e la stesura.

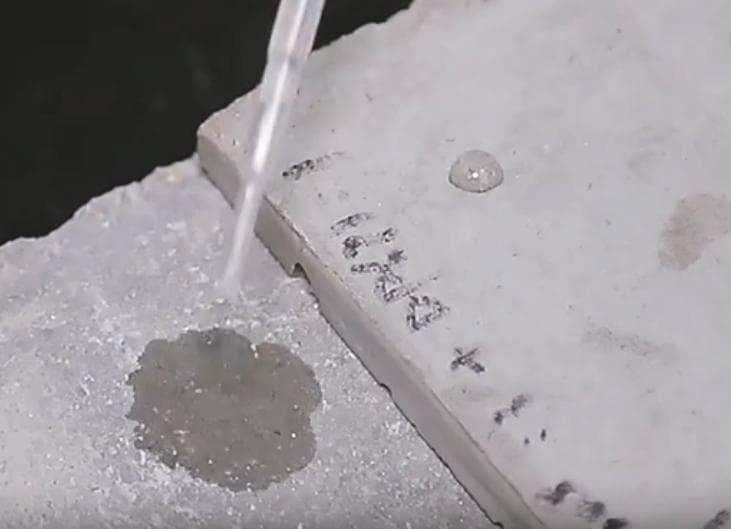

Ritenzione idrica: Il MHEC, con eccellenti proprietà di ritenzione idrica, aiuta a prevenire la rapida perdita di acqua dall'adesivo, consentendo un tempo sufficiente per il posizionamento e la regolazione delle piastrelle.

Tempo di impostazione: Il tempo di presa dell'adesivo per piastrelle può essere controllato scegliendo il grado MHEC appropriato, assicurandosi che sia in linea con i requisiti specifici dell'installazione.

Forza di adesione: Il MHEC contribuisce alla forza di adesione dell'adesivo per piastrelle, favorendo un forte legame tra le piastrelle e il substrato.

-

Compatibilità con altri ingredienti

È fondamentale garantire la compatibilità tra il MHEC e gli altri ingredienti della formulazione dell'adesivo per piastrelle, come il cemento, le cariche e gli additivi. I problemi di compatibilità possono causare problemi di prestazioni e influire sulla qualità complessiva dell'adesivo per piastrelle. È consigliabile consultare i fornitori o i produttori di MHEC per determinare la compatibilità del prodotto con il resto della formulazione.

-

Considerazioni specifiche per l'applicazione

La scelta di MHEC per l'adesivo per piastrelle deve considerare anche i requisiti specifici dell'applicazione. Fattori come il tipo di substrato, le dimensioni e il peso delle piastrelle, le condizioni ambientali e i metodi di installazione possono influenzare la scelta del grado di MHEC più adatto. Ad esempio, le piastrelle di grande formato possono richiedere MHEC con proprietà tissotropiche migliorate per evitare cedimenti e garantire una copertura adeguata.

-

Qualità e coerenza

La qualità e la consistenza di MHEC sono fondamentali per garantire l'affidabilità e le prestazioni degli adesivi per piastrelle. MHEC di alta qualità garantisce che l'adesivo mantenga le sue proprietà durante tutto il processo di applicazione, portando a risultati coerenti e affidabili.

In conclusione, il MHEC svolge un ruolo fondamentale negli adesivi per piastrelle, migliorandone le prestazioni e garantendo la qualità delle installazioni di piastrelle. La comprensione delle proprietà e delle considerazioni sul MHEC è essenziale per selezionare il prodotto giusto per applicazioni specifiche, contribuendo in ultima analisi al successo dei progetti di adesivi per piastrelle.

Lascia una risposta