How Long Does Self-Leveling Concrete Take to Dry?

In modern construction, speed, precision, and surface quality are crucial. Self-leveling compounds, also known as self-levelers, are widely used to create smooth, flat surfaces on concrete subfloors before installing tiles, vinyl, laminate, or hardwood flooring.

The drying time of self-leveling underlayments can significantly affect project schedules, installation efficiency, and cost control. As a leading manufacturer of construction chemical additives, we provide insight into what impacts drying time and how to optimize it.

What Is Self-Leveling Concrete?

Self-leveling concrete is a special type of cement that flows easily and settles into a flat surface without needing a lot of troweling. It’s often used to smooth out uneven subfloors or to cover old concrete, wood, or tile before installing new flooring.

It’s mixed with water on-site and poured directly onto the surface. Once poured, it spreads out like pancake batter and fills in dips and low spots. After that, it needs time to dry and cure.

Average Drying Time for Self-Leveling: General Guidelines

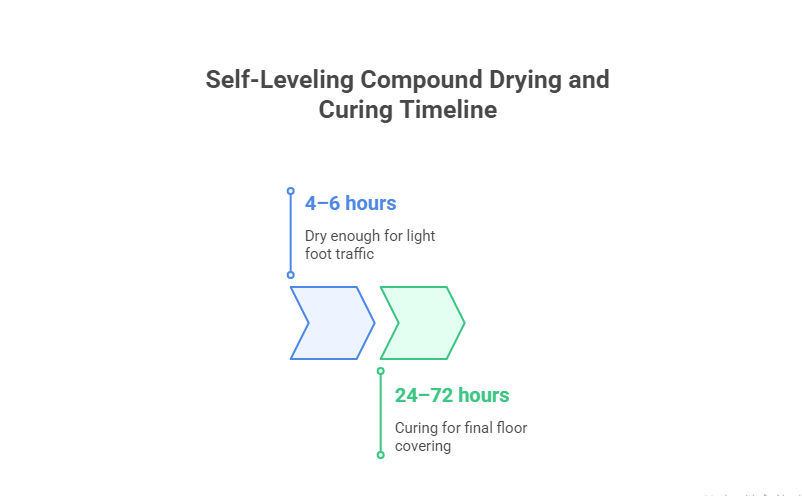

In typical conditions (20°C / 68°F and 50% relative humidity), self-leveling compounds dry enough for light foot traffic in 4–6 hours. However, this doesn’t mean the floor is ready for the final floor covering. For installations like tile or vinyl, curing may take 24 to 72 hours, depending on the product and site conditions. Drying time for self-leveling is much shorter than the concrete drying time. If you're interested, you can read our related article on How Long Does Concrete Take to Dry.

| Activity | Estimated Time |

|---|---|

| Light Foot Traffic | 4–6 hours |

| Installation of Tile | 16-24 hours |

| Installation of Vinyl/Wood | 48–72 hours |

| Full Cure | Up to 7 days |

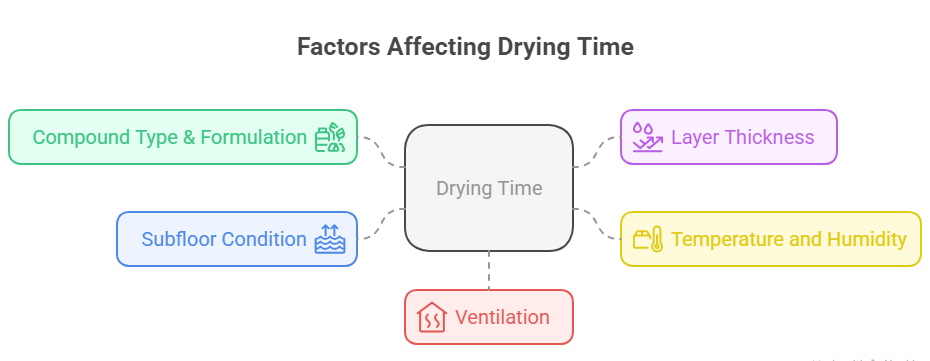

Key Factors That Affect Drying Time

Drying time isn’t the same for every project. Several factors can speed up or slow down the process:

1. Compound Type & Formulation

Some compounds are formulated for fast-drying applications, drying in as little as 2–4 hours. Others are designed for deeper pours or thicker applications and require longer curing. Additives like accelerators or retarders in the mix can speed up or slow down the drying process.

| Compound Type | Estimated Time |

|---|---|

| Cement-based compounds | 24-48 hours |

| Fast-setting compounds | 4–6 hours |

| Gypsum-based compounds | up to 3 days |

Tip from Mikem: Formulators can adjust drying time with additives like calcium formate (a drying accelerator) or choose the right cellulose ether for moisture retention control.

2. Layer Thickness

Drying time increases with thickness. A 3mm layer may dry in 4 hours, but a 10mm layer may require more than 24 hours. Manufacturers usually specify drying times per millimeter.

| Layer Thickness | Estimated Time |

|---|---|

| 3mm layer | 4 hours |

| 10mm layer | 24 hours |

| >10mm layer | 48 hours and more |

3. Temperature and Humidity

Self-levelers dry faster in warm weather and slower in cold conditions. The ideal temperature for drying is around 21°C to 24°C (70°F to 75°F).

4. Subfloor Condition

Some subfloors absorb moisture (like wood), while others (like tile or sealed concrete) don’t. Non-absorbent surfaces may cause slower drying.

5. Ventilation

Good airflow supports evaporation and consistent drying. Poor ventilation can lead to surface drying faster than the underlying layers, causing cracks.

How to Know When It’s Dry

Here are some simple ways to check if your self-leveling floor is dry:

- Touch Test: Gently touch the surface. If it feels firm and cool but not sticky or soft, it’s probably dry enough to walk on.

- Color Change: Many self-levelers change color slightly as they dry. Check the edges—they often dry first.

- Time Check: Refer to the product’s label. If the instructions say 4 hours for light foot traffic, give it at least that long before walking on it.

- Moisture Test (for flooring installation): Use a moisture meter or plastic sheet test to make sure the floor is dry enough to install materials like vinyl, wood, or tile.

Tips to Speed Up Drying (Without Compromising Quality)

If you’re working on tight deadlines, here are some smart ways to accelerate drying:

- Use fast-drying products specifically formulated for short timelines.

- Control the environment: Maintain room temperature between 20–25°C and humidity under 50%.

- Apply thin layers where possible.

- Use a fan or dehumidifier to improve air circulation and moisture removal.

- Avoid sealing the surface too soon—let it breathe.

Note from Mikem: Our construction-grade additives allow formulators to balance drying speed and workability while preventing surface cracking.

[Related reading: What is concrete made of]

Optimize Self-Leveling Compounds Performance with Mikem Additives

At Mikem, we work with global manufacturers of dry-mix mortars and flooring materials to develop high-performance self-leveling compounds. Our construction chemical additives enhance key properties across the entire application process:

🔹Hydroxypropyl Methylcellulose (HPMC)

Mikem HPMC acts like a "performance booster" for self-leveling mortar, making it easier to apply, stronger, and more crack-resistant. HPMC can also be used to enhance wall putty performance. It optimizes self-leveling mortar by:

- Improving flowability for effortless spreading and a perfectly flat surface.

- Enhancing water retention, preventing premature drying, and ensuring full cement hydration for maximum strength.

- Extending workability time, allowing adjustments during large-area pours.

- Boosting adhesion to substrates, reducing delamination risks.

🔹Redispersible Polymer Powder (RDP)

Redispersible polymer powder (RDP) is a key ingredient in self-leveling flooring compounds. When mixed with water, it forms a flexible, glue-like film that improves the material’s performance in several ways:

- Strengthening bonding to concrete, wood, and other substrates.

- Increasing flexibility, preventing cracks under stress.

- Enhancing abrasion resistance, ideal for high-traffic areas.

- Reducing shrinkage cracks, ensuring long-term durability.

🔹Powder Defoamer

Trapped air can weaken self-leveling mortar and create surface defects. Mikem’s powder defoamer helps create smoother, stronger, and more efficient self-leveling surfaces while being environmentally friendly:

- Removing air bubbles instantly, improving workability, and reducing labor time.

- Preventing pinholes and voids, ensuring a smooth, professional-grade finish.

- Supporting eco-friendly construction by minimizing material waste.

🔹Polypropylene Fiber (PP Fiber)

Polypropylene fiber is a valuable addition to self-leveling formulations where crack resistance and structural integrity are key concerns.

- Reinforces the compound to reduce shrinkage cracks

- Improves dimensional stability during the curing phase

- Enhances tensile and flexural strength of the hardened layer

Final Thoughts

The drying time of a self-leveling compound depends on many factors, including material composition, environment, and thickness. Understanding these variables helps project planners make informed decisions and avoid costly delays.

As a trusted supplier in the construction industry, Mikem provides not just high-quality additives but also technical support and formulation guidance. Whether you are manufacturing flooring underlayments, repairing concrete surfaces, or developing specialty leveling systems, we’re here to help you create faster, stronger, and more reliable products.

Contact Us

📲 To learn more about how Mikem’s chemical additives can improve your self-leveling compounds, contact our team or request a free product sample today.

Leave a Reply