Hydroxypropyl methylcellulose (HPMC), as a versatile polymeric material, finds extensive applications across multiple sectors including construction, pharmaceuticals, food, and daily chemicals. Its stability directly determines the quality and performance of downstream products. Therefore, understanding the key factors affecting HPMC stability holds significant importance for production, storage, and application processes.

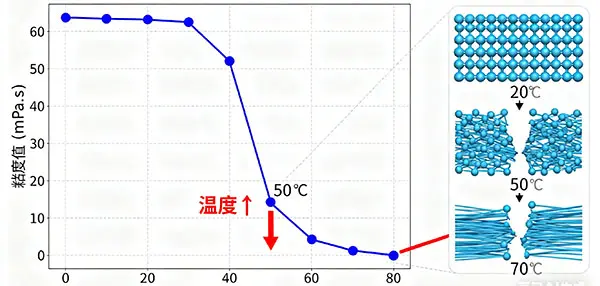

I. Temperature:

The Core Factor Affecting the Structure and Properties of Hydroxypropyl Methylcellulose.

Temperature is one of the primary factors contributing to the deterioration of hydroxypropyl methylcellulose performance.

- Effects of High-Temperature Environments: When ambient temperatures exceed 60°C, hydroxypropyl methylcellulose molecular chains are prone to thermal degradation, resulting in reduced viscosity and weakened water retention properties. For instance, in construction mortar applications, excessive storage temperatures can diminish the water retention capacity of hydroxypropyl methylcellulose, causing rapid moisture loss and cracking in the mortar, thereby compromising construction quality.

- Effects of Low-Temperature Environments: While low temperatures do not directly cause hydroxypropyl methylcellulose degradation, they slow its dissolution rate. Preparing hydroxypropyl methylcellulose solutions at low temperatures may lead to clumping, compromising solution uniformity and thereby reducing its application effectiveness.

Therefore, whether during post-production storage or pre-application processing, hydroxypropyl methylcellulose must be maintained at ambient temperatures between 5°C and 30°C, avoiding prolonged exposure to extreme high or low temperatures.

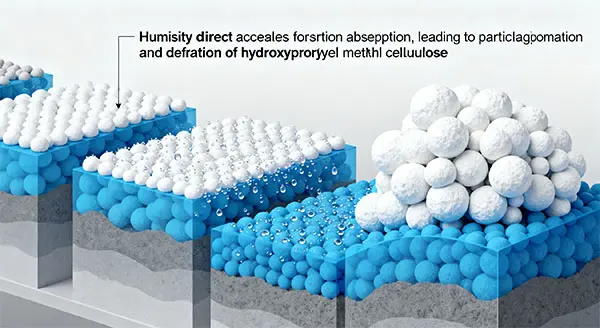

II. Humidity:

A Key Factor Contributing to the Moisture Absorption and Deterioration of Hydroxypropyl Methylcellulose.

Hydroxypropyl methylcellulose exhibits a certain degree of hygroscopicity. Excessively high environmental humidity can cause changes in its physical and chemical properties:

- Moisture Absorption and Caking: When relative humidity exceeds 65%, hydroxypropyl methylcellulose powder readily absorbs moisture from the air, leading to caking. This not only impairs solubility but also affects dispersion within products. For instance, in pharmaceutical applications, moisture-absorbed hydroxypropyl methylcellulose used as a tablet binder can cause inconsistent tablet hardness and abnormal disintegration rates.

- Microbial Growth: High humidity environments may also provide conditions conducive to the proliferation of microorganisms such as mold and bacteria. The metabolic activities of these microorganisms can disrupt the molecular structure of hydroxypropyl methylcellulose, leading to performance degradation and potentially generating harmful substances that compromise product safety.

To mitigate humidity effects, hydroxypropyl methylcellulose must be packaged in sealed containers (such as kraft paper bags lined with polyethylene film) and stored in a dry, well-ventilated warehouse. Desiccants may be placed within the warehouse to maintain relative humidity between 40% and 60%.

III. Storage Methods:

The Key Factor Determining the Shelf Life of Hydroxypropyl Methylcellulose.

In addition to temperature and humidity, improper storage methods can also accelerate the performance degradation of hydroxypropyl methylcellulose:

- Packaging Integrity: If the packaging of hydroxypropyl methylcellulose is damaged, it may come into direct contact with air, moisture, and impurities, leading to moisture absorption and contamination. Therefore, packaging integrity must be inspected during storage. Partially used products should be resealed promptly after opening to prevent prolonged exposure.

- Stacking Method: Excessive stacking height may cause compression and caking of hydroxypropyl methylcellulose at the bottom layer, while also impairing warehouse ventilation and increasing localized humidity. It is recommended to stack in layers, with a maximum height of 3 layers. Maintain a 10-15cm clearance from warehouse walls and floors to ensure adequate air circulation.

- Avoid co-storage with harmful substances: Hydroxypropyl methylcellulose may undergo chemical reactions when stored alongside strong oxidizing agents, strong acids, strong alkalis, or other chemicals, leading to molecular chain breakage or structural modification. For instance, exposure to strong acids can destroy the ether bonds in hydroxypropyl methylcellulose, causing it to lose its original thickening and water-retention properties.

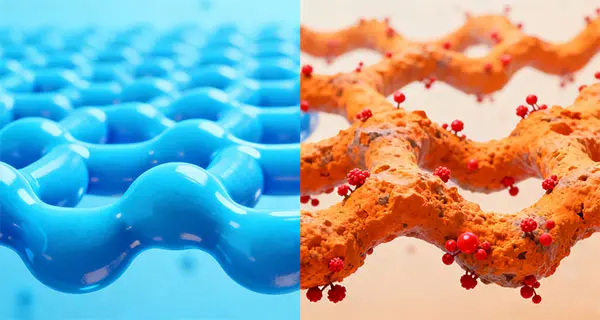

IV. Purity and Impurities:

Intrinsic Factors Affecting the Essential Stability of Hydroxypropyl Methylcellulose.

The purity and impurity content of hydroxypropyl methylcellulose fundamentally affect its stability:

- Impact of Raw Material Impurities: If raw materials used in hydroxypropyl methylcellulose production (such as refined cotton, propylene oxide, or methyl chloride) contain significant impurities (e.g., metal ions, residual organic compounds), this accelerates the degradation process. For instance, metal ions (such as iron or copper ions) catalyze the oxidation reaction of hydroxypropyl methylcellulose, shortening its shelf life.

- Impact of Production Processes: High-quality hydroxypropyl methylcellulose requires rigorous purification procedures (such as washing, drying, and impurity removal). Incomplete purification during production may leave residual salts or unreacted raw materials that compromise its stability. For instance, residual chloroform can undergo slow decomposition, adversely affecting the chemical stability of hydroxypropyl methylcellulose.

Therefore, when selecting hydroxypropyl methylcellulose, attention should be paid to the product's purity specification (typically ≥99%), with priority given to brands employing mature production processes and stringent quality control.

V. pH Value:

A Critical Factor Affecting the Stability of Hydroxypropyl Methylcellulose Solutions.

In liquid applications (such as coatings, cosmetics, and pharmaceutical oral solutions), the pH value of hydroxypropyl methylcellulose solutions significantly impacts their stability:

- Effects of Strong Acid/Strong Base Environments: Hydroxypropyl methylcellulose exhibits stable performance within a pH range of 3-11. If the pH falls below 3 (strongly acidic) or exceeds 11 (strongly basic), its ether bonds undergo hydrolysis, leading to decreased viscosity and solution separation. For example, in acidic food additive applications, the system pH must be controlled between 4 and 7 to prevent hydroxypropyl methylcellulose degradation.

- The role of buffer systems: When pH fluctuations are significant in an application scenario, adding buffering agents (such as citric acid-sodium citrate buffer) can stabilize the system's pH value, thereby protecting the structure and properties of hydroxypropyl methylcellulose.

VI. Light Exposure:

A Potential Factor Accelerating the Oxidative Degradation of Hydroxypropyl Methylcellulose.

Prolonged exposure to sunlight (especially ultraviolet radiation) causes hydroxypropyl methylcellulose to undergo photo-oxidation reactions, leading to molecular chain breakage and performance degradation:

- The destructive effects of ultraviolet light: Ultraviolet radiation excites the active groups within hydroxypropyl methylcellulose molecules, triggering oxidative degradation. This manifests as yellowing of the product and reduced viscosity. For instance, in outdoor architectural coatings, degradation of hydroxypropyl methylcellulose due to UV exposure leads to diminished adhesion and increased susceptibility to peeling.

- Storage Recommendations for Light Avoidance: Warehouses storing hydroxypropyl methylcellulose should avoid direct sunlight. If short-term outdoor storage is necessary, cover with shade cloth. Product packaging may also utilize opaque materials (such as opaque kraft paper) to minimize the impact of light exposure on its stability.

How to Effectively Improve the Stability of Hydroxypropyl Methylcellulose?

Considering the aforementioned influencing factors, the stability of hydroxypropyl methylcellulose can be ensured through the following measures:

1.Control storage conditions: Room temperature (5-30°C), dry (relative humidity 40%-60%), light-protected, well-ventilated; avoid co-storage with harmful substances.

2. Ensure packaging integrity: Use sealed, opaque professional packaging; reseal promptly after opening.

3. Optimize application conditions: Adjust pH (3-11) and temperature according to application scenarios; avoid strong acids/bases and high-temperature environments;

4.Select premium products: Prioritize high-purity hydroxypropyl methylcellulose produced under standardized manufacturing processes to ensure stability from the source.

Conclusion

The stability of hydroxypropyl methylcellulose is influenced by multiple factors including temperature, humidity, storage methods, purity, pH levels, and exposure to light. Neglecting any of these aspects may compromise its performance, ultimately affecting the quality of downstream products. Whether manufacturers, distributors, or end-users, all stakeholders must thoroughly understand these influencing factors. By adopting scientifically sound storage and application practices, the functional value of hydroxypropyl methylcellulose can be maximized.

Leave a Reply