Water based adhesive is a kind of environmentally friendly adhesive prepared by using natural polymer or synthetic polymer as binder, and water as solvent or dispersant, replacing toxic organic solvents that are polluting to the environment.

Commonly used water based adhesive mainly includes water-based paint, latex paint and so on. The common water based adhesive formulation: 60% to 70% polymer emulsion, 3% to 5% thickener, 0.5% to 2% crosslinking agent, 1% to 2.5% stabilizer, 0.5% to 1% organic acid, 30% to 35% water.

The water based adhesive formulation

| Ingredients | Content | Benefits |

| Polymer emulsion | 60% to 70% | With adhesive properties |

| Thickener | 3% to 5% | Adjust the viscosity |

| Crosslinking agent | 0.5%~2% | Improve strength and water resistance |

| Stabilizer | 1%~2.5% | Prevent emulsion separation and degradation |

| Organic acid | 0.5%~1% | Control pH value |

| Water | 30%~35% | Adjust viscosity and dilute emulsion |

Unique water based adhesive formulation

Below is the water based adhesive formulatio recommended by Melacoll's technical experts, including the specific materials used, for your reference:

VAE emulsion: As the main film forming material of adhesives, ethylene acetate-ethylene copolymer emulsion (VAE emulsion) is selected, and the content is about 40%-50%. VAE emulsion has good adhesion, water resistance and flexibility to ensure that the adhesive forms a strong and lasting bond on the surface of different building materials.

Mikem Chemical can offers VAE emulsions of consistent quality.

Plasticizer: Add dibutyl phthalate (DBP), accounting for about 3%-5%. Its function is to reduce the intermolecular force of the polymer, increase the flexibility and fluidity of the adhesive, improve the infiltration of the adhesive to the adhesive, and thus improve the bond performance.

Aggregate, Filler: selection of light calcium carbonate, the content of about 20%-30%. Calcium carbonate can adjust the consistency of the adhesive, reduce the cost, and enhance the cohesion and mechanical strength of the adhesive, improve its aging resistance.

Thickening Agent: hydroxyethyl cellulose (HEC), the amount of about 0.5%-1%. It can effectively adjust the viscosity of the adhesive, so that it has good operability in the construction process, not easy to flow, and ensure that the adhesive is evenly distributed on the surface of the adhesive. Our proposed product is MELACOLL-HE3000B/5000B. The product has sold well all over the world for many years.

Preservatives: isothiazolinone preservatives, add about 0. 1% -0.3%. It is used to inhibit the growth of microorganisms, prevent the deterioration of adhesives during storage and use, and extend the shelf life of products.

Water: surplus, as a dispersing medium, so that the components are evenly mixed to ensure the stability and construction performance of the adhesive.

Preparation Process

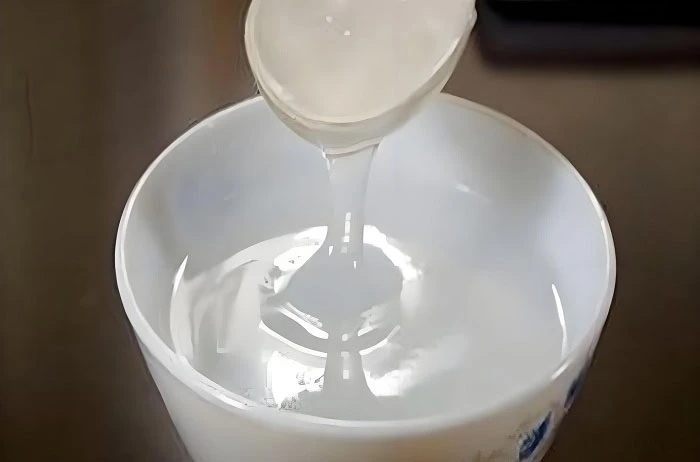

(1) In the reactor with a stirring device, add an appropriate amount of water first and start stirring.

(2) Slowly add hydroxyethyl cellulose and stir continuously until completely dissolved to form a uniform solution.

(3) Add VAE emulsion and dibutyl phthalate in turn, stir evenly, so that each component is fully mixed.

(4) Gradually add light calcium carbonate, control the adding speed, avoid clumping, stir until evenly dispersed.

(5) Finally, add the isothiazolinone preservative and stir for a few minutes to ensure that the preservative is evenly dispersed in the adhesive.

The water-based building adhesive obtained by the above formula and preparation process has the advantages of high bond strength, good water resistance, environmental protection and non-toxic, and is suitable for bonding a variety of building materials, such as wood, ceramics, concrete, etc., to meet the different needs of building construction.

Our unique water-based adhesive formula is formulated by our experts in the hpmc factory laboratory after many years of testing, and has achieved good results in practical applications, combined with our products for better results! For more information, please contact us in time.

Leave a Reply