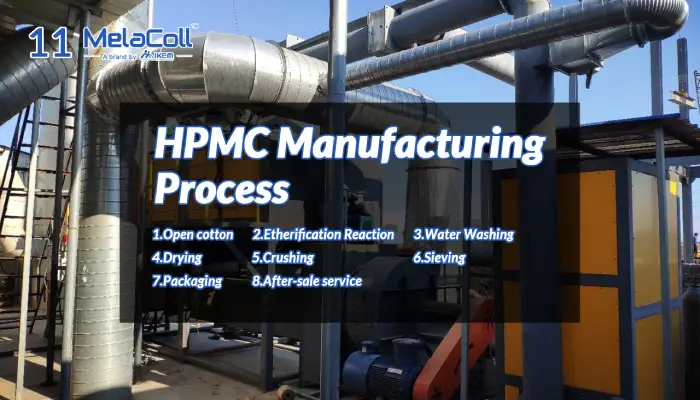

Melacoll HPMC manufacturing process includes 9 steps: cotton opening, etherification, washing, drying, crushing, sieving, packaging, and after-sales service. As a HPMC manufacturer in china, MIKEM has its own HPMC factory and we can ensure HPMC quality and provide best price.

1. Two main HPMC production process

There are two main production processes based on the capacity of different manufacturers:

One is the one-step etherification method, the hydroxypropylation reaction and the methylation reaction are carried out simultaneously.

The other is the step-by-step etherification method, which means that the hydroxypropylation operation and the methylation operation are carried out separately,

2. HPMC manufacturing process includes 8 steps

1. To make a change from cotton-shaped to powder. This process is in our open cotton workshop.

2. Combine Methyl Chloride with Propylene Oxide to complete the etherification reaction.

We need important equipment in this process, that is a reactor with a strong agitating device. For the time being, in our plant, we have 12 horizontal reactors and 6 vertical reactors. And the annual capacity of our cellulose products is 40,000 tons per year.

3. Water washing,

4. Drying,

5. Crushing,

6. Sieving. This is where we decide the fineness of the batch.

7. The last step in HPMC manufacturing process is the packaging. In this process, we have an automatic packaging machine. and with a professional UI desining teams, we also support customize trademarks! And then we deliver our goods to every corner of the world!

And where’s step 8?

Our after-sale service that will We promise that you will be able to find our responsible team to solve your difficulties in time when you have queries after the sale.

Therefore, hpmc manufacturing needs to be supported by strong hpmc factory. After years of development, Chinese chemical enterprises are fully capable of meeting various demands, especially the strong enterprises led by Mikem!

Leave a Reply