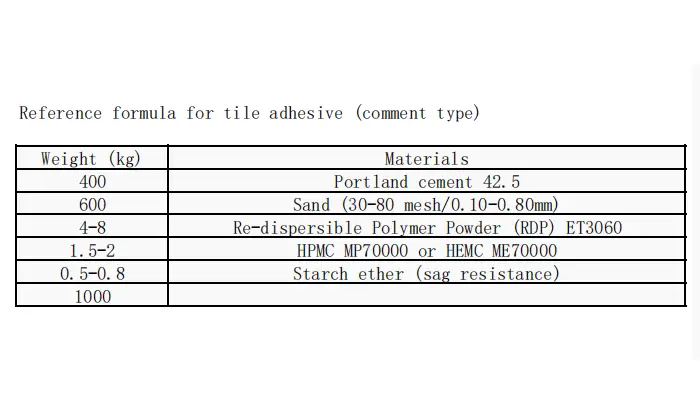

Cement based tile adhesive formulations include:

- Cement 42.5(400kg),

- Sand 30-80 mesh, 0.10-0.80mm(600kg),

- Cellulose ether Melacoll HP 70000 or ME 70000(1.5-2),

- Redispersible powder Mikrant ET3060(4-8kg).

- And other addictives, such as starch ether (0.5-0.8kg).

Cement and sand are the main raw materials of tile adhesive. Cellulose ether and redispersible polymer powder modified the properties of tlle adhesive.

1. Cement - main components of cement based tile adhesive

Cement is an inorganic gelling material. And it is the main auxiliary material for cement based tile adhesive formulation. cement tile adhesive is also the earliest material used to lay tiles. The amount of cement added to the tile adhesive formulation is generally 40%.

2. Sand

Sand is aggregate in the cement based tile adhesive formulation. Sand adjusts the consistency of the tile adhesive, so its particle size is very important. 20-mesh sand will have obvious graininess. It will affect the smoothness of the tile adhesive. The water content is generally less than 0.5%, the mud content is less than 3-5%.

3. Cellulose ether

The cellulose ethers in cement based tile adhesive formulation are methyl celluloses. It has high water retention, such as HPMC. HPMC is a thickener in tile adhesive formulations and provides good water retention.

But, the amount of cellulose ether used in the tile adhesive formulation should be strictly controlled. Otherwise, it will cause the surface of the tile adhesive to peel. Generally speaking, in the cement based tile adhesive formulation, the additional amount of HPMC is 1.5-2. The specific addition amount is also affected by the local climate, temperature, humidity, etc.

Cellulose ether plays two roles in the cement based tile adhesive formulation.

1. Thickening property. HPMC can thicken the freshly mixed mortar to have a certain wet viscosity and prevent segregation.

2. Water retention. Water retention is also the most important characteristic. It helps to maintain the amount of free water in the mortar. So after the mortar is constructed, the cementitious material has more time to hydrate. High-quality HPMC can disperse in cement mortar. And it can wrap all solid particles, and form a wetting film. The water is released over a long period of time. The cementitious material reacts with water to ensure bond strength and compressive strength.

3.1 Hpmc for tile adhesive

1. HPMC is an important material in cement based tile adhesive formulation. It is a dry mix material that is easy to mix and does not produce lumps. HPMC for tile adhesive formula shortens the working time and makes construction faster and more effective. It can improve workability and reduce costs.

2. Improve the efficiency of paving tiles by prolonging the drying time.

3. Provide excellent adhesion effect and improve the anti-skid effect of tiles.

4. Redispersible polymer for tile adhesive formulation

The redispersible polymer powder mainly used in the market includes:

- vinyl acetate and ethylene copolymer powder,

- vinyl acetate and ethylene and higher fatty acid vinyl ester ternary copolymer powder,

- vinyl acetate and higher fatty acid vinyl ester copolymer powder,

- vinyl acetate Esters and acrylates and higher fatty acid vinyl ester ternary copolymer rubber powder.

Tile adhesives can be divided into C1 and C2 according to the bonding strength. C1 tile adhesive is suitable for tiles smaller than 30 by 30cm. Its bonding strength is at least 0.5MPa. C1 tile adhesives must be modified with a high content of dispersible polyumer powder. C2 tile adhesive has a wider range of applications. The bonding strength is at least 1mpas. According to customers, the bonding strength of glazed tiles is much lower. In order to achieve a reliable bonding effect, an appropriate amount of dispersible redispersible powder must be added to cement based tile adhesive formulation.

RDP powder in ceramic tile adhesive formulations can enhance bond strength to all substrates. It increases tensile strength, improves workability, and increases flexural strength and water retention.

Afterlong time, the mortar became hardened. RDP also can provide high flexibility or impact resistance and improved wear resistance.

5. MELACOLL cement based tile adhesive formulation

MELACOLL chemical adhesive advantage in tile adhesive formulation:

1. Improve heat resistance and freeze-thaw resistance. Adding Melacoll products to tile adhesive is a better choice. The heat resistance and freeze-thaw resistance of tile adhesives are improved. Excellent adhesion to a wide variety of substrates in harsh climates with long open and correction times in high-temperature environments.

2. Improved sag resistance. Melacoll provides long-lasting and effective polymer modification. It can prevent tiles from peeling off walls. Prevents cracks between substrate and tile.

3. Water retention. The water retention capacity of Melacoll allows the tile adhesive to have enough time for hydration without losing water. It reduces solidification shrinkage and avoids cracking and falling off.

4. Improve workability. Melacoll's products have good leveling properties. At the same time, starch ether products are also provided to provide good lubricity. Please contact us for starch ether.

6. In summary

Cement based tile adhesive formulation is different according to its characteristics. In actual operation, most workers will choose formulas according to substrates and tiles. At the same time, it will change at any time with different regions, climates, and temperatures. But, the main components in the tile adhesive formula are not much different. Cement, sand, cellulose, and polymer powder are inseparable. With MIKEM’s wide range of products, you can formulate the perfect tile adhesive. If you are interested in our products or want to order our products, please contact us.

When applying tile adhesive, you will use a tile adhesive applicator, etc.. How to Apply the Tile Adhesive?You can find the answer in this blog.

Leave a Reply