Concrete is one of the most widely used construction materials in everything from driveways and sidewalks to foundations and patios. But despite its widespread use, one critical question persists among homeowners and contractors alike: How long does concrete take to dry?

The answer isn’t as simple as checking the clock. Concrete drying and curing are complex processes influenced by multiple factors, including weather conditions, mix composition, and project specifications.

In this guide, we’ll explain the concrete curing process, explore the key variables that affect drying time, and provide expert tips to ensure your project sets perfectly.

What Does It Mean for Concrete to “Dry”?

Before we get into specific drying times, it’s important to clarify what we mean when we refer to concrete “drying.” The process of concrete curing is actually different from simply “drying.” In construction terms, drying refers to the evaporation of water from the surface of the concrete, whereas curing refers to the hardening and strengthening of the concrete as it undergoes a chemical reaction known as hydration.

- Drying: This is the process where the water in the concrete evaporates from the surface.

- Curing: The chemical reaction between the cement and water in concrete that hardens and strengthens the material over time.

Thus, concrete doesn’t truly dry in the traditional sense. It cures over time, gaining strength and durability as it does. Now, let’s dive deeper into how long these processes take.

4 Stages of Concrete Curing

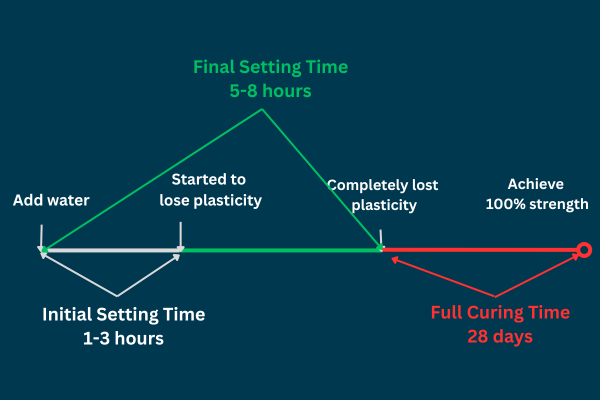

Concrete curing goes through three main stages: Initial Set, Final Set, Strength Development, and Full Cure. Each stage is essential for the concrete to achieve its full strength and durability. Here’s a simplified breakdown:

1. Initial Setting (1-3 hours)

When concrete is first poured, it begins to stiffen and lose its plasticity. During this stage, which typically lasts 1-3 hours, the concrete can start to hold its shape and may support some weight. However, it’s still quite fragile, and you should avoid walking on it or placing heavy objects on it. It's still in the early stages of hardening.

2. Final Setting (5-8 hours)

After the initial set, the concrete continues to harden. This phase typically lasts 5-8 hours and is influenced by factors like temperature, humidity, and the mix used. At this point, the concrete can withstand light foot traffic and some handling, but it’s still not fully solid. It’s getting stronger, but it’s not yet at its maximum strength.

3. Strength Development

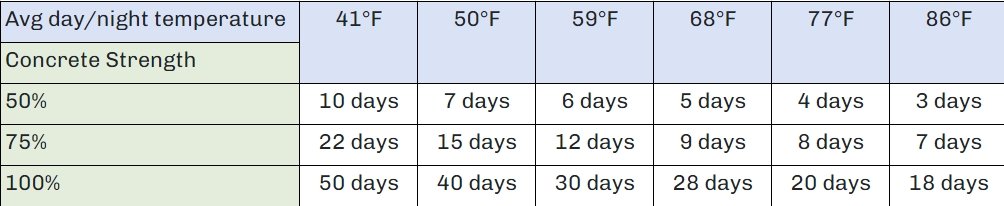

Concrete typically reaches 25% of its design strength within a few hours, 50% in 3-7 days, and in 7- 14 days, concrete usually reaches about 75% of its ultimate strength. It continues to cure and gain strength gradually.

4. Full Curing Time (up to 28 days)

While the concrete may feel dry to the touch after 24-48 hours, it’s still far from being fully cured. Concrete needs up to 28 days to fully cure and reach its maximum strength. During this time, the concrete continues to harden and gain strength, and after 28 days, it’s considered fully cured, though its strength might keep improving a little beyond that. For most residential and commercial projects, 28 days is the standard time to allow concrete to reach about 90% to 100% of its ultimate strength.

Factors That Affect Concrete Drying Time

The time it takes for concrete to dry and set is influenced by a variety of factors, each of which can either speed up or slow down the curing process. Understanding these factors can help ensure the concrete reaches its desired strength and durability at the right time. Here are some of the most important factors that affect concrete drying time:

1. Type of Cement

Different types of cement have different chemical compositions, which directly impact how fast concrete sets. For instance, rapid-hardening cement will set much quicker than regular cement. This is particularly useful in situations where faster construction or early strength is required, but it’s important to select the right type based on project needs.

2. Water-Cement Ratio

The water-to-cement ratio is a critical factor in concrete's drying time. A higher water content results in a more diluted mixture, which slows down the hydration process and therefore prolongs the setting time. On the other hand, a lower water content speeds up the setting process but can make the concrete more difficult to work with. Additionally, the type, size, and grading of aggregates in the mix can also affect the setting time, as these materials influence the amount of water needed and how it interacts with the cement.

3. Temperature and Humidity

The environmental conditions play a significant role in how quickly concrete cures. Warmer temperatures accelerate the hydration reaction of cement, meaning the concrete sets faster. Conversely, cooler temperatures slow down the hydration process, which means longer curing times.

Humidity also affects the curing process: in dry conditions, moisture in the concrete evaporates quickly, speeding up the setting time. However, in humid environments, the moisture is retained longer, which can extend the curing time.

At 86°F temperatures, the initial setting time of concrete is usually shorter, ranging from about 1.5 to 3.5 hours. As for the final setting time, it will usually be between 6 and 10 hours.

4. Concrete Thickness

Thicker layers of concrete will naturally take longer to dry and cure. While the surface of thin concrete slabs may dry relatively quickly, the interior of thicker sections of concrete will take longer to harden. For example, a 4-inch-thick slab will likely take longer to cure completely compared to a 2-inch-thick slab.

In conclusion, several factors—such as the type of cement, water-to-cement ratio, temperature, humidity, and the use of additives—affect the drying time of concrete. By controlling these variables, you can ensure that concrete sets at the right pace, providing the desired strength and durability for your project.

5. Additives

At Mikem, we offer a range of high-quality concrete additives designed to help control setting time. These include water reducers, retarders, and accelerators, each serving a specific purpose:

- Water Reducers: The most common is Polycarboxylate Superplasticizer (PCE). These additives reduce the amount of water required for a given amount of cement, improving the mix's workability. They can also extend the setting time, giving workers more time to pour and finish the concrete. However, excessive use of water reducers can make the mix too thin and reduce its strength.

- Retarders: These are designed to slow down the cement hydration process, extending the setting time. They’re particularly useful in hot weather or in situations where concrete needs to be transported over long distances before being poured.

- Accelerators: These additives speed up the setting and hardening of concrete, which is helpful in cold weather or when fast project completion is necessary. However, they should be used carefully to avoid compromising the final strength of the concrete.

How to Speed Up Concrete Drying

While concrete requires time to cure properly, there are a few things you can do to accelerate the process without compromising its strength:

- Use a Faster Setting Mix: As mentioned earlier, there are rapid-setting concrete mixes available that can help you finish a project quickly. If time is of the essence, these mixes may be a good option.

- Increase Temperature: In cold weather, warming the concrete with heated enclosures or blankets can speed up the curing process. Be cautious with extreme heat, however, as it can lead to cracking.

- Improve Airflow: Ensuring proper airflow around your concrete can help moisture evaporate more quickly, aiding the drying process.

- Use Curing Compounds: Curing compounds can help prevent moisture from evaporating too quickly, especially in hot, dry conditions, allowing the concrete to cure properly.

- Cover with Plastic Sheets: In hot, dry weather, covering concrete with plastic sheets can help retain moisture and slow down the drying process, which will improve the overall curing process.

- Use Chemical Additives: There are special chemical additives, like PVA Fiber, that you can mix into concrete. These speed up the curing time without weakening the concrete. They’re useful when fast results are needed, especially in cold weather.

[Related reading: How Long Does Self-Leveler Take to Dry]

Best Practices for Curing Concrete

Ensuring proper curing is essential to achieving the best results with your concrete. Below are some tips and techniques for optimal curing:

1. Keep Concrete Moist

For the first few days, concrete should be kept moist to ensure that hydration continues. This can be achieved by spraying water over the surface, covering the concrete with wet burlap, or using curing compounds to trap moisture.

2. Protect from Extreme Weather

If you’re working in hot or cold conditions, you may need to take additional measures. In hot weather, use wet coverings to prevent rapid drying. In cold weather, use blankets or heated enclosures to keep the temperature steady and prevent freezing.

3. Curing Compounds

Curing compounds are liquid chemicals that form a membrane over the surface of the concrete to retain moisture. This method is particularly useful for larger areas where manual watering may be difficult.

4. Don’t Disturb the Concrete

Avoid placing heavy loads or equipment on freshly poured concrete. For the first 24-48 hours, the concrete is still vulnerable to damage, so it’s important to keep it undisturbed.

5. Regularly Monitor Temperature and Humidity

Use thermometers and humidity sensors to monitor the curing environment. Adjust your curing methods as needed depending on the weather conditions.

FAQs About Concrete Drying and Curing

1. How long before you can walk on concrete?

It's best to wait at least 24 hours before walking on freshly poured concrete. While concrete begins to harden within a few hours, it needs time to reach sufficient strength to handle foot traffic without risk of damage.

2. Can I walk on concrete after 4 hours?

You'd better not, walking on concrete after 4 hours is possible, but it’s not ideal. The concrete may still be soft and prone to leaving marks or indentations, especially if it's under a heavy weight. It’s safer to wait 24 hours to ensure it has reached enough strength for normal use.

3. How long should concrete cure before putting weight on it?

Concrete typically needs about 24-48 hours before it can bear lightweight. However, to ensure the concrete has reached a stronger point, it’s best to wait 7 days for medium-weight use and 28 days for full strength.

4. How long does it take for a concrete driveway to dry?

A concrete driveway usually takes around 24-48 hours for surface drying, but it takes about 28 days to fully cure and reach maximum strength. For light vehicles, you can generally drive on it after 7 days, but for heavy traffic, it's best to wait the full month.

5. How long does it take for a concrete patio to dry?

A concrete patio typically takes 24-48 hours for surface drying. Like other concrete, it takes about 28 days for the patio to fully cure and achieve its maximum strength.

6. How long does self-leveling concrete take to dry?

Self-leveling concrete usually takes around 2 to 4 hours to dry enough for light foot traffic, but it can take up to 24 hours for the surface to fully dry before applying any weight or further treatments.

7. How long does it take for 4-inch concrete to dry?

For 4-inch-thick concrete, it generally takes around 24-48 hours for it to dry enough for light use. Full curing to reach its maximum strength will take about 28 days.

8. How long does 6 inches of concrete take to cure?

A 6-inch-thick concrete slab will take slightly longer to cure than thinner slabs. It will usually take about 24-48 hours for it to dry for light use, but full curing will still take around 28 days for the concrete to achieve its ultimate strength and durability.

Conclusion

Concrete curing is a crucial step in the construction process, impacting the strength, durability, and overall quality of your project. While concrete generally takes about 28 days to fully cure, the exact time depends on various factors such as temperature, humidity, water content, and concrete mix. By understanding these factors and following best practices for curing, you can ensure that your concrete reaches its full strength potential and stands the test of time. If you want to learn more about concrete, you can click on this ultimate guide.

Whether you’re building a sidewalk, driveway, foundation, applying tile adhesive, or any other concrete structure, paying attention to the curing process is essential for a successful, long-lasting result.

Leave a Reply