Anti-dispersion is an important technical indicator to measure the quality of anti-dispersant. Hydroxypropyl methyl cellulose (HPMC) is a water-soluble polymer compound, also known as water-soluble resin or water-soluble polymer. It increases the consistency of the mixture by increasing the viscosity of the mixing water. It is a hydrophilic polymer material. It can be dissolved in the water to form a solution or dispersion. Experiments show that when the amount of naphthalene-based superplasticizer increases, the addition of water-reducing agent will reduce the dispersion resistance of newly prepared cement mortar. This is because the naphthalene-based superplasticizer is a surfactant.

When the superplasticizer is added to the mortar, the superplasticizer is arranged directionally on the surface of the cement particles so that the surface of the cement particles has the same electric charge. This electric repulsion forces the flocculation structure formed by the cement particles be disassembled, and the water wrapped in the structure is released, which will cause the loss of a portion of the cement. At the same time, it was found that with the increase of HPMC content, the dispersion resistance of newly prepared cement mortar can be getting better and better.

1. The HPMC dispersion toward Strength characteristics Of mortar

The hydroxypropyl methyl cellulose (HPMC) underwater non-dispersible concrete admixture is applied in the bridge foundation engineering of the expressway, and the design strength grade is C25.

According to basic experiments, the cement dosage is 400kg, the compound mixed with silica fume is 25kg/m3, the optimal HPMC dosage is 0.6% of the cement dosage, the water-cement ratio is 0.42, the sand ratio is 40%, and the dosage of naphthalene-based superplasticizer is 8% of the cement dosage, the concrete specimen in the air is 28d, the average strength value is 42.6MPa, the concrete prepared underwater at a drop height of 60mm is 28d, the average strength value is 36.4MPa, the strength ratio of concrete formed in the water to that formed in the air is 84.8%, the effect is comparably more obvious.

1. The addition of HPMC has a significant retarding effect on the mortar mixture. With the increase of the HPMC content, the setting time of the mortar is successively extended. With the same HPMC content, the setting time of mortar formed underwater is longer than the mortar formed in the air. This characteristic is beneficial for underwater concrete pumping.

1. The addition of HPMC has a significant retarding effect on the mortar mixture. With the increase of the HPMC content, the setting time of the mortar is successively extended. With the same HPMC content, the setting time of mortar formed underwater is longer than the mortar formed in the air. This characteristic is beneficial for underwater concrete pumping.

2. The newly prepared cement mortar mixed with hydroxypropyl methyl cellulose has good cohesive properties. It almost has no bleeding.

3. The mixture amount of hydroxypropyl methyl cellulose (HPMC) and the water demand of mortar show a decrease first and then a significant increase.

4. The addition of water-reducing agent improves the problem of increasing water demand of mortar, but its mixing amount must be controlled reasonably, otherwise the underwater dispersion resistance of newly prepared cement mortar will sometimes be reduced.

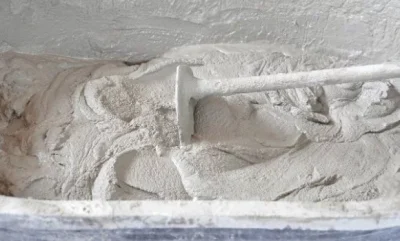

5. There is little difference in structure between the cement mortar specimen mixed with HPMC and the blank cement mortar specimen. The cement mortar specimens poured in the water and in the air have little difference in structure and density. The cement mortar specimen of 28d formed under water is slightly loose. The main reason is that the addition of HPMC greatly reduces the loss and dispersion of cement poured in the water, but at the same time it also reduces the density of the mixture made up of cement and stones. In a project, while ensuring the nondispersion effect under water, the amount of HPMC should be minimized.

6. By adding hydroxypropyl methyl cellulose (HPMC) underwater non-dispersible concrete admixture and controlling the dosage is beneficial to the strength. The pilot project shows that the strength ratio of concrete formed in the water to that formed in the air is 84.8%, the effect is comparably more obvious.

MIKEM PRODUCT FOR CEMENT-BASED MORTARS

As high-performance additives designed for special mortars, our MelaColl™ cellulose ether products and Mikrant RDP products are widely used in cement mortors and can significantly strengthen cement-based mortars’ properties and performances in the following ways:

- Improve adhesion

- Improve workability and consistency

- Improve water retention

- Accelerate air entertaining and increase lubricity

- Improve hydrophobicity

- Increase durability

If you are looking for excellent hydroxypropyl methyl cellulose (HPMC) product for cement-based mortars, please do not hesitate to CONTACT US for more information about products or a sample! We are always ready to answer you with one-to-one service and tailored formula!

Leave a Reply