Self-leveling mortar is a new type of construction mortar material that has been vigorously promoted in recent years. Using RDP on self-leveling mortar can solve effectively some intractable problems, such as floor cracks.

Relying on the self-weight and self-leveling of the slurry during the construction process, it forms a smooth, high-strength, abrasion-resistant, economical and practical base layer after solidification. Self-leveling mortar has the advantages of good fluidity, easy construction, fast leveling speed, time-saving, thin leveling layer thickness, high ground flatness, high compressive strength, etc., which effectively solves the poor flatness sanding of traditional ground materials. However, some problems have not been effectively resolved, such as floor cracks and poor flexibility. Taking WACKER powder as an example, we analyze RDP's impact on external wall insulation systems and self-leveling.

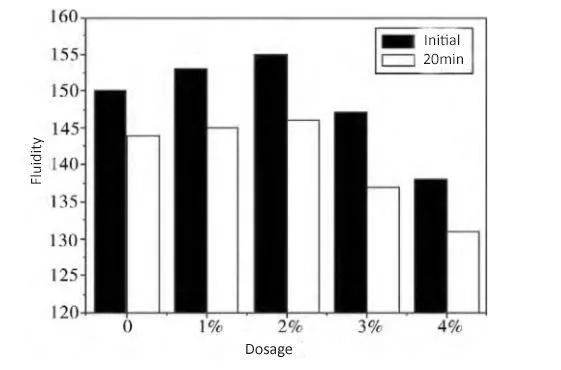

1. Influence of the dosage of WACKER polymer powder on fluidity and 20min fluidity

The RDP on self-leveling usually lubricates the construction of the mortar, protects the water affinity of the colloid when it is dispersed, and the viscosity increases the cohesion of the construction mortar, thereby improving the workability. The dry powder mortar is mixed with different proportions of dispersible polymer powder, and its fluidity and fluidity retention is tested, as shown in Figure 1

Figure 1 The influence of different dosages of WACKER Polymer Powder on fluidity

The influence of dispersible polymer powder on the fluidity of mortar changes with the increase of its content. When the mixing amount of RDP on self-leveling reaches 2%, the fluidity of the self-leveling mortar reaches 155mm; the fluidity is excellent, no bleeding occurs on the surface, and the surface condition after leveling is good. When the rubber powder content reaches 3%~4%, the fluidity has a downward trend, and the retention of 20 minutes decreases. When the rubber powder content reaches 3%~4%, the fluidity has a downward trend, and the retention of 20 minutes decreases.

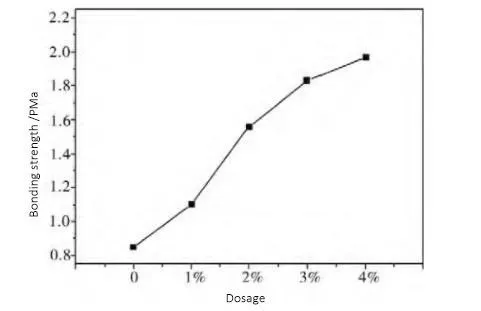

2. The effect of different content of WACKER Polymer Powder on the bond strength

In the construction of self-leveling mortar, the self-leveling layer is a second additional layer. The construction thickness is relatively thin, and there is no curing or the curing time is very short. Through experiments, it can be found that adding a certain amount of RDP on self-leveling can provide long-term and reliable bonding strength, and the bonding strength of self-leveling mortar increases significantly with the increase in the amount of RDP on self-leveling (see Figure 2). Moreover, the bond strength failures occurred inside the polystyrene board rather than at the interface, indicating that the bond strength was good.

Figure 2 The effect of different content of WACKER Polymer Powder on the bond strength

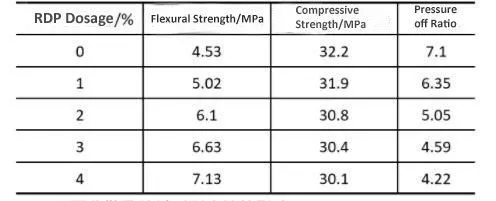

3. The influence of redispersible polymer powder on flexural and compressive strength

In constant experimental conditions, the influence of the amount of dispersible polymer powder on the flexural and compressive strength of cement-based mortar is shown in Table 3. As shown in Table 3, the compression ratio (compressive strength/flexural strength) gradually decreases with the increase in the amount of dispersible polymer powder. This indicates that the brittleness of the self-leveling floor material gradually decreases with the rise of RDP on self-leveling, reducing the elastic modulus and improving its crack resistance, reflecting the improvement of the flexibility of the mortar.

Table 3 The influence of dispersible polymer powder on flexural and compressive strength

4. The effect of WACKER Polymer Powderon abrasion resistance

A self-leveling mortar prepared with different content of dispersible polymer powder was used to test its abrasion resistance. The experiment shows that the incorporation of RDP on self-leveling can significantly improve abrasion resistance. As the dosage increases, the wear resistance of the mortar increases, and the wear resistance value decreases, indicating that the addition of RDP on self-leveling mortar improve the wear resistance of cement, while its film-forming performance in the self-leveling of cement is also outstanding, which ensuring its comprehensive implementation. Using RDP on self-leveling mortar can improve the fluidity of self-leveling mortar with the addition of sprinkled polymer powder, increase the wear resistance of the mortar after hardening, and reduce the possibility of cracking.

5. Conclusion

1. Using RDP on self-leveling mortar can significantly improve its performance, increase its flexural and compressive strength, and enhance the adhesion to the base surface.

2. Polymer powder has the unique advantages of small dosage, good plasticizing effect, good reinforcement effect, and increased wear resistance, which helps solve the technical problems of self-leveling mortar preparation.

Leave a Reply